American code and standard mandate the minimum distance between two welds in a pipeline.But most company specification will give some minimum distance that you have to maintain between two nearby welds. This is to avoid overlapping of heat affected zones.

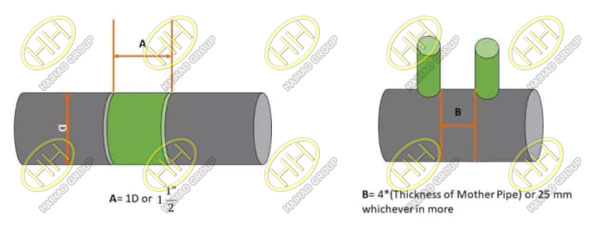

The thumb rule is that the minimum distance between adjacent butt welds is 1D. If not, it is never closer than 1-1/2″. This is supposed to prevent the overlap of heat affected zones. In the image, you can see what I am trying to explain to you.Here, A and B are two weld joints.The minimum distance between these two joints should be the one-time diameter of the pipe. So, if your pipe is 4″ NPS the distance should be 4″. If this is not possible, it should not be less than 1½”.

The minimum distance between two welds in a pipeline

The minimum spacing of circumferential welds between centerlines shall not be less than four times the pipe wall thickness or 25 mm whichever is greater. Here, you can see the example. If you have branch welding on a pipe, then the distance between two adjacent branches or nearest girth weld should be four times the pipe wall thickness or 25 mm whichever is greater. Please note that these are thumb rule and vary from company to company.

Haihao Group is experienced for the welded pipes or fittings.Contact us if you need the welded piping goods.Email:sales@haihaogroup.com