Electrode electroslag resurfacing is the use of conductive slag resistance heat to melt the resurfacing material and base material. Electroslag resurfacing welding is one of the methods of resurfacing welding.

Electroslag resurfacing with electrode has the following advantages compared with submerged arc resurfacing with electrode:

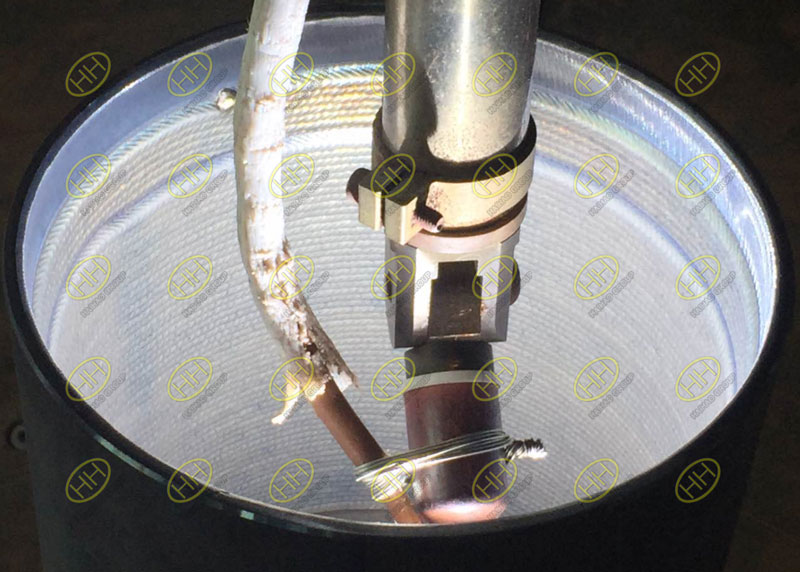

Weld Cladding Piping Products

1) High deposition efficiency, 50% higher than submerged arc resurfacing welding at medium current;

2) The resurfacing layer is well formed, not prone to slag inclusion and other defects, and the surface quality is excellent. The surface roughness is less than 0.5mm (more than 1mm in submerged arc resurfacing), so the surface does not need mechanical processing, saving materials and time.

3) There is very little burn loss and unfavorable element increment of alloying elements in the electrode, and the plasticity and toughness of resurfacing layer are higher than that of submerged arc welding.

4) Due to the narrow carbon diffusion layer and small martensite band width in the joint fusion zone, the performance of the joint fusion zone is better than that of buried arc resurfacing with pole.

Weld Cladding Process

Electrode electroslag resurfacing welding has a high heat input, so it is generally used for resurfacing welding 50 ~ 200mm thick wall workpiece.

In Hebei Haihao Group, the electroslag resurfacing welding is widely used in the production of flanges,pipe fittings and other pipeline products, with mature technology and great advantages.If you want to know more about our piping products,please email to us:sales@haihaogroup.com