Butt welding is one type of welding joint methods.In the butt welding process, the two parts of material put together parallel along a edge in one line.Butt welding joints could be done by a large machine continuously or a portable welding machine operated by a welder.Butt welding joint is an economical and reliable method of joining materials without any additional components.

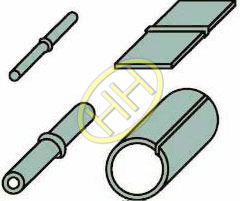

Butt Welding Plate And Pipe

The butt welding process could be used for both metal and plastic.When two steel sheets are laid side by side and welded together along the line,this is a typical example of butt welding joint.

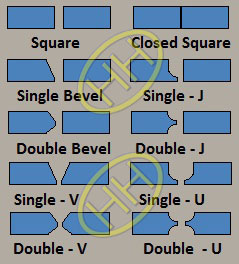

Plate With V Groove For Butt Welding

If the thickness of the material is thin,the square and plain edge of material is ok for butt welding joint.If the material is thicker for welding,the edges should be beveled to form a single V groove or double V groove,the double V groove is used for the thickest thickness,it means the material is beveled on both side.And the filler will be placed and Welding on both side.The double V butt welding is commonly used for the very thicker and large objects.

Butt Welding End Groove For Different Thickness

In Haihao, a lot of butt welding joints in our products.

1. Our main pipe fittings products are butt welding pipe fittings,their ends are plain end or bevel end for butt welding connection.

2. Large size pipe fittings are produced from steel plate, they are welded in body,not seamless . Those fittings are produced in butt welding method.

Pipe Bevel End For Butt Welding

3. The weld neck flange, when it is welded to the pipes,the welding joint is butt welding, the long weld neck flange is same.

4. Piping prefabrication, for such fabrication products, when we design it , we prefer to use the butt welding method as the joints. Because butt welding joints is very strong and secure for materials.