For engineers and procurement specialists working in piping systems—especially in the oil & gas, petrochemical, and power industries—understanding international pipe fitting standards is essential. With a wide range of specifications like MSS SP-97, MSS SP-95, ASME B16.11, and ASME B16.3, choosing the correct fitting isn’t always straightforward.

It just so happens that the order we recently delivered to our Indonesian customers includes a variety of standard products.In this article, we will break down these standards, explain their key features, and help you determine when and where to use each.

MSS SP-97 ASTM A182 GR. F5A weldolets

MSS SP-97: For Integrally Reinforced Branch Outlet Fittings

MSS SP-97 is the standard for integrally reinforced forged branch outlet fittings, also known as Olets (e.g., Weldolet, Threadolet, Sockolet). These fittings are used to create 90° or angled branches from a larger run pipe to a smaller branch pipe.

Connection Types: Threaded (Threadolet), Socket Weld (Sockolet), Butt Weld (Weldolet)

Material Examples: A105N carbon steel, stainless steel grades, alloy steels

Common Applications: Pressure piping, high-temperature systems, or where reinforcement is critical

This standard ensures proper reinforcement and pressure integrity, making it ideal for high-stress industrial systems.

MSS SP-95 A234 WPB Galvanized Eccentric Swage Nipple

MSS SP-95: Swage Nipples and Bull Plugs

MSS SP-95 covers swage nipples and bull plugs, typically used for pipeline transitions and line terminations.

Fitting Types: Concentric and Eccentric Swage Nipples

End Connections: Threaded, plain end, beveled end

Material Examples: A234 WPB, A234 WPB Galvanized (for corrosion protection)

Swage nipples are useful for reducing pipe diameter in a straight line or offset configuration and are often applied in tight spaces or flow-controlled systems.

ASME B16.11 forged pipe fittings

ASME B16.11: Forged Steel Socket-Weld and Threaded Fittings

ASME B16.11 defines small-diameter forged fittings for socket-weld and threaded connections, typically up to NPS 4 (DN 100).

Common Types:

- 90° & 45° Socket Weld Elbows

- Socket Weld Tees

- Threaded Elbows and Tees

- Unions and Couplings

Material Example: A105N for carbon steel, stainless steels

These fittings are ideal for high-pressure, small bore piping systems and are widely used in oil & gas, chemical, and steam systems.

ASME B16.3: Malleable Iron Threaded Fittings

ASME B16.3 focuses on malleable iron threaded fittings, such as reducing couplings, elbows, and tees.

Common Materials: A197 and A197 Galvanized

Size Range: 1/8″ to 6″

Applications: Low-pressure plumbing, water lines, air systems

Galvanized versions offer corrosion resistance, especially for outdoor or humid environments.

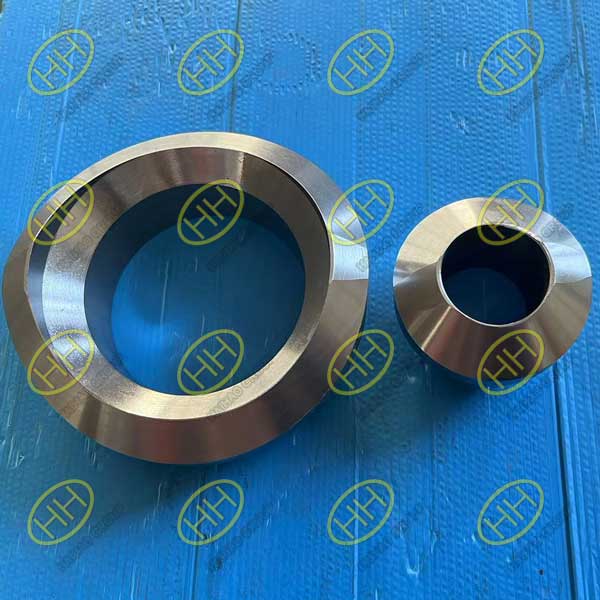

ASME B16.5 A182 F316L weld neck flanges

ASME B16.5 & B16.47: Flanges

ASME B16.5: Covers flanges from NPS ½ to 24

ASME B16.47: For large-diameter flanges NPS 26 to 60, divided into Series A & B

Face Types:

FF (Flat Face): Used with cast iron and other brittle materials

RF (Raised Face): Most common for industrial applications

RTJ (Ring-Type Joint): For high-pressure/high-temperature use

Materials: A105N, A105N Galvanized, stainless steel grades

Choosing the Right Standard for Your Project

When selecting fittings for your project, consider the following:

- Pressure Rating & System Requirements

- Connection Type Preference (Socket Weld, Threaded, Flanged)

- Material Compatibility with Medium and Temperature

- Installation Space Constraints

Working with a knowledgeable supplier like Haihao Group, which supports a full range of international standards, ensures correct product selection and code compliance.

Whether you’re designing a high-pressure refinery system or maintaining a low-pressure utility line, choosing the correct fitting standard is crucial. MSS and ASME standards each serve specific applications, and understanding their scope helps prevent over-specification or compatibility issues.

If you need assistance with pipe fitting selection, Haihao Group offers comprehensive technical support and supplies a wide range of products manufactured to MSS, ASME, and other global standards.Email:sales@haihaogroup.com