What is full-encirclement reinforcing saddle?

Full-encirclement reinforcing saddles are used to provide reinforcement for branch outlets in accordance with ASME B31.3, B31.4, B31.8 and other applicable design codes.Although full-encirclement reinforcing saddles are designed to fully encircle the run pipe, they are not designed to be pressure retaining. In order to avoid gas entrapment during welding and to prevent pressure containment,should a leak develop underneath the saddle, Full-Encirclement Reinforcing Saddles are provided with a vent hole.

Types of full-encirclement reinforcing saddles:

There are 5 types of full-encirclement reinforcing saddles commonly used in the industry:

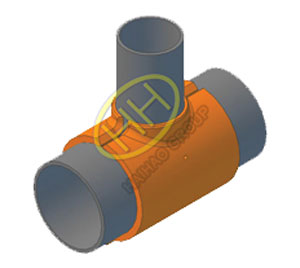

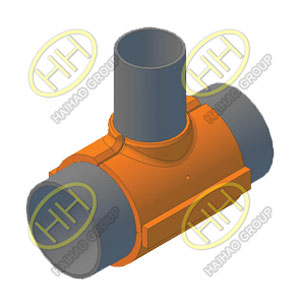

Pipeline full encirclement reinforcing saddles part 1 drawing

Part 1 – Single piece construction,split into two equal halves through the run and the branch.

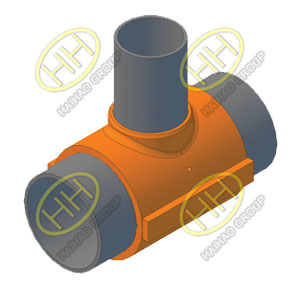

Pipeline full encirclement reinforcing saddles part 2 drawing

Part 2 – Single piece construction,split longitudinally through the run perpendicular to the branch.

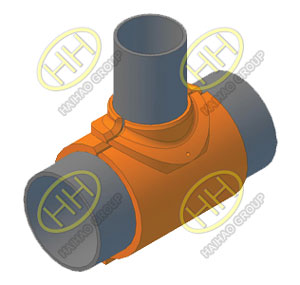

Pipeline full encirclement reinforcing saddles part 3 drawing

Part 3 – Two piece construction, composed of a run cylinder welded to a partial saddle,split into two equal halves through the run and the branch.

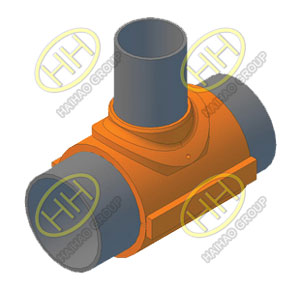

Pipeline full encirclement reinforcing saddles part 4 drawing

Part 4 – Two piece construction,composed of a run cylinder welded to a partial saddle,split longitudinally through the run perpendicular to the branch.

Pipeline full encirclement reinforcing saddles part 5 drawing

Part 5 – Single piece construction,cut into three sections by splitting through the branch and through the run perpendicular to the branch.

Our full encirclement reinforcing saddles are manufactured in following materials:

Carbon steel: A234 WPB & A234 WPC

Low temp steel: A420 WPL-6

Alloy steel: A234 WP-11,WP-22,WP-5

High yield materials: MSSSP75 WPHY-42 through Y-70, A860 WPHY-42 through Y-70

Haihao Group can supply full-encirclement reinforcing saddles with full size or reduced branch outlets.If you have any questions,please feel free to email us:sales@haihaogroup.com