To an outsider,pipes and tubes may seem like they should be synonymous.To a marine engineer,the measurements, standards and language used to distinguish the two couldn’t be more different.In fact,differences in nomenclature and measurements could cause quite the headache if tubes and pipes were mistakenly assumed to be interchangeable.

The Main Differences Between Pipes and Tubes

Tubes can come in different shapes like square,rectangular and cylindrical.Pipe is always cylindrical or round. While rigid tubes are frequently used in structural applications,copper and brass tubes can be rather flexible.Pipes are typically always rigid and resistant to bending.When it comes to classification,pipes use schedule and nominal diameter.For example, a pipe could have a 250mm nominal diameter and a schedule of 80.Tubes are classified by their outside diameter measurement and thickness.A copper tube,for instance,could be 10 mm with a 2 mm thickness.

Pipes accommodate larger applications with sizes that range from a half-inch to several feet.Tubes are generally used in applications that require smaller diameters.While 10-inch pipes are common, it’s rare that you will come across a 10-inch tube.Tubes are often put to use in applications that require precise outside diameters,like with cooler tubes,heat exchanger tubes and boiler tubes.Pipes have a pressure rating and are schedule,which is why they are often used to carry fluids that must be contained.The thickness of tubes increases in standard increments such as 1 mm or 2 mm.Pipe thickness depends on the schedule,so there is no fixed increment. Joining pipes is more labor intensive as it requires welding,threading or flanges.Tubes can be joined quickly and easily with flaring,brazing or couplings,but for this reason,they don’t offer the same stability.

Tubing

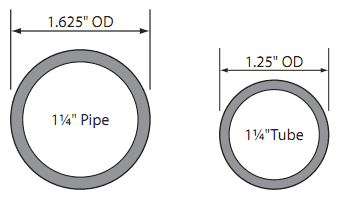

Tubing is generally used for structural purposes and the OD is an important and exact number.Tubing size is specified by OD and the wall thickness (WT);and the measured OD and stated OD are generally within very close tolerances of each other.Tubing is usually more expensive than pipe due to tighter manufacturing tolerances. Interestingly,while the stated and measured OD’s of tubing are almost exact most of the time, copper tubing generally has a measured OD that is 1/8″ larger than stated OD.As such,maybe it should be called copper pipe. However,stainless steel,aluminum,and steel tubing all have measured and stated OD’s that are exact or very close.

Pipe

Pipes are categorized as tubular vessels used in pipeline and piping systems, and commonly transport gases or fluids. They are specified by “Nominal Pipe Size” (NPS) and Schedule (wall thickness).NPS is a size standard established by the American National Standards Institute (ANSI), and should NOT be confused with the various thread standards such as NPT and NPSC. The manufacturing of Nominal Pipe Sizes from 1/8″ to 12″ is based on a standardized nominal outside diameter (OD) that is different from the measured OD. NPS pipe 14″ and up have measured OD’s that correspond to the nominal size. The reason many people, including plumbers, engineers, and others, mistakenly believe NPS refers to the ID on smaller pipes is because of how the standard was originally defined.The standardized OD was originally defined so that a pipe with a standardized OD and wall thickness typical of the period, would have a pipe ID that was approximately equal to the nominal size of the pipe.For example,3″ Schedule 40 NPS has an outside diameter and wall thickness that very,very roughly gives it an inside diameter of 3″. Regardless of the wall thickness the nominal OD of a pipe will not change.

There you have the differences explained as simply as possible. Of course if something isn’t clear certainly let us know.