o Welded steel pipe is a seam steel pipe.Its production is to bend the tube blank (steel plate and steel strip) into a required cross-sectional shape and size by various forming methods, and then use different welding methods to weld the seams. The process of obtaining steel pipes..

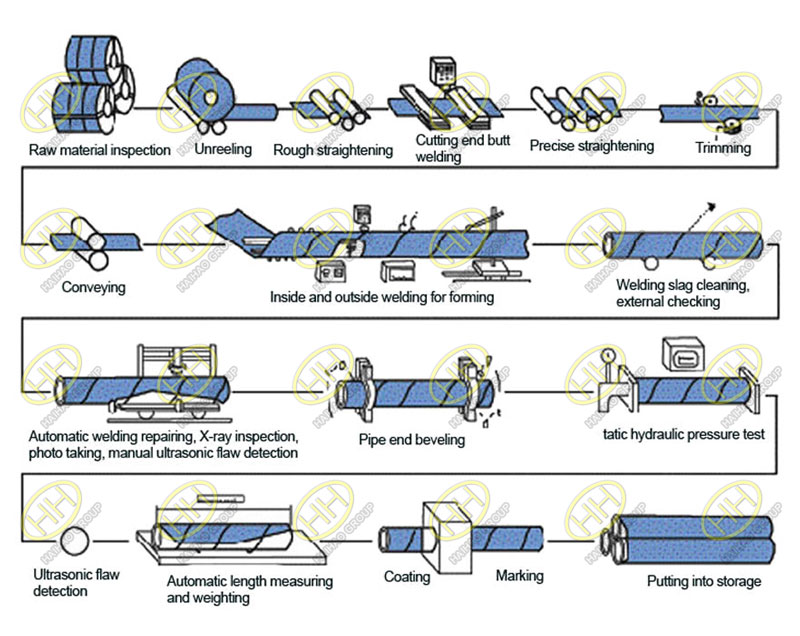

1.Spiral submerged arc welding (SSAW) steel pipes process:

A.The raw materials of spiral steel pipes are strip coils, welding wires and fluxes.

B. Before forming, the strip is leveled, trimmed, planed, surface cleaned and conveyed, and pre-curved.

C. Weld gap control device is used to ensure that the weld gap meets the welding requirements, and the pipe diameter, misalignment amount and weld gap are strictly controlled.

D. After cutting into a single steel pipe, the first three of each batch of steel pipes must undergo a strict first inspection system to check the mechanical properties, chemical composition, fusion status, surface quality of the steel pipe and non-destructive inspection to ensure that the pipe manufacturing process is qualified. Only then can it be officially put into production.

Spiral submerged arc welding (SSAW) steel pipes process

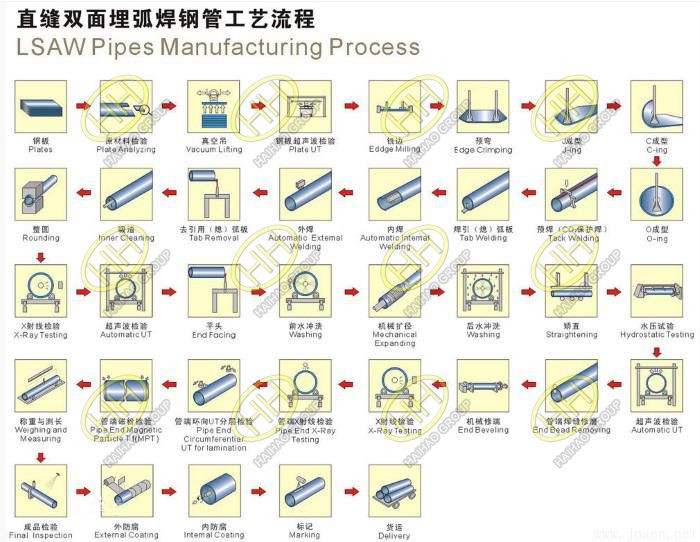

2.Longitudinal submerged arc welding (LSAW) process:

LSAW generally uses steel plates as raw materials, and through different forming processes, it uses double-sided submerged arc welding and expanded diameter after welding to form welded pipes.

LSAW Pipes Manufacturing Process

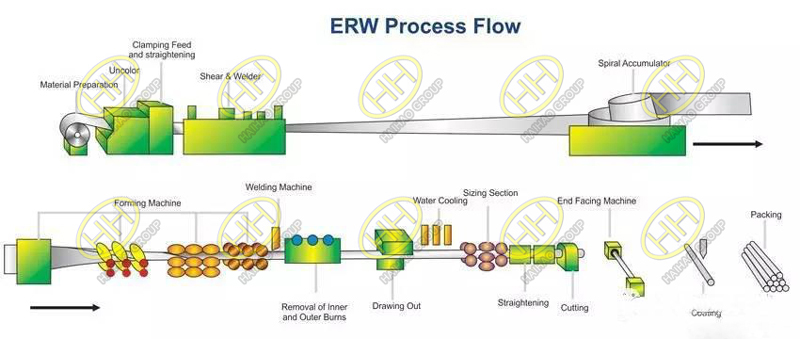

3.Electric resistance welding (ERW) pipe process

ERW pipe ,the hot-rolled coil is formed by a forming machine, and the skin effect and proximity effect of high-frequency current are used to heat and melt the edge of the tube blank. To achieve production.

ERW Process Flow

As a professional piping supplier,we can supply steel pipes,pipe fittings,flanges in different dimensions,standards,materials.If you want to know more about our products,please feel free to contact us.Email:sales@haihaogroup.com