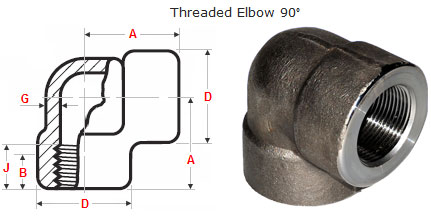

Definition and Details of Threaded Fittings ASME B16.11

Threaded Fittings General

Threaded joints probably represent the oldest method of joining piping systems. Like Socket Weld fittings, threaded fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. The dimensional standards for taper pipe threads are given in ASME B1.20.1. That document gives all required dimensions including number of threads per inch, pitch diameter, and normal engagement lengths for all pipe diameters.

- Threaded piping is commonly used in low-cost, noncritical applications such as domestic water, fire protection, and industrial cooling water systems.

- Threaded fittings are normally made of cast gray or malleable iron, cast brass or bronze, or forged alloy and carbon steel.

- They are available in three pressure ratings: Class 2000, 3000 and 6000.

All fittings on this page are described, are provided with NPT thread, ASME B1.20.1. The American National Pipe Thread Tapered, is the best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal. NPT has a tapered male and female thread which seals with Teflon tape or jointing compound.

| Class | DN | NPS | B | D | C(Ave) | C(Min) | J | K |

| 3000 | 6 | 1/8″ | 21 | 17 | 22 | 3.18 | 6.4 | 6.7 |

| 8 | 1/4″ | 21 | 17 | 22 | 3.18 | 8.1 | 10.2 | |

| 10 | 3/8″ | 25 | 19 | 25 | 3.18 | 9.1 | 10.4 | |

| 15 | 1/2″ | 28 | 22 | 33 | 3.18 | 10.9 | 13.6 | |

| 20 | 3/4″ | 33 | 25 | 38 | 3.18 | 12.7 | 13.9 | |

| 25 | 1″ | 38 | 28 | 46 | 3.68 | 14.7 | 17.3 | |

| 32 | 1 1/4″ | 44 | 33 | 56 | 3.89 | 17 | 18 | |

| 40 | 1 1/2″ | 51 | 35 | 62 | 4.01 | 17.8 | 18.4 | |

| 50 | 2″ | 60 | 43 | 75 | 4.27 | 19 | 19.2 | |

| 65 | 2 1/2″ | 76 | 52 | 92 | 5.61 | 23.6 | 28.9 | |

| 80 | 3″ | 86 | 64 | 109 | 5.99 | 25.9 | 30.5 | |

| 100 | 4″ | 106 | 79 | 146 | 6.55 | 27.7 | 33 | |

| 6000 | 6 | 1/8″ | 21 | 17 | 22 | 3.18 | 6.4 | 6.7 |

| 8 | 1/4″ | 25 | 19 | 25 | 3.3 | 8.1 | 10.2 | |

| 10 | 3/8″ | 28 | 22 | 33 | 3.51 | 9.1 | 10.4 | |

| 15 | 1/2″ | 33 | 25 | 38 | 4.09 | 10.9 | 13.6 | |

| 20 | 3/4″ | 38 | 28 | 46 | 4.32 | 12.7 | 13.9 | |

| 25 | 1″ | 44 | 33 | 56 | 4.98 | 14.7 | 17.3 | |

| 32 | 1 1/4″ | 51 | 35 | 62 | 5.28 | 17 | 18 | |

| 40 | 1 1/2″ | 60 | 43 | 75 | 5.56 | 17.8 | 18.4 | |

| 50 | 2″ | 64 | 44 | 84 | 7.14 | 19 | 19.2 | |

| 65 | 2 1/2″ | 83 | 52 | 102 | 7.65 | 23.6 | 28.9 | |

| 80 | 3″ | 95 | 64 | 121 | 8.84 | 25.9 | 30.5 | |

| 100 | 4″ | 114 | 79 | 152 | 11.18 | 27.7 | 33 | |

| 9000 | 6 | 1/8″ | 25 | 19 | 25 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4″ | 28 | 22 | 33 | 6.6 | 8.1 | 10.2 | |

| 10 | 3/8″ | 33 | 25 | 38 | 6.98 | 9.1 | 10.4 | |

| 15 | 1/2″ | 38 | 28 | 46 | 8.15 | 10.9 | 13.6 | |

| 20 | 3/4″ | 44 | 33 | 56 | 8.53 | 12.7 | 13.9 | |

| 25 | 1″ | 51 | 35 | 62 | 9.93 | 14.7 | 17.3 | |

| 32 | 1 1/4″ | 60 | 43 | 75 | 10.59 | 17 | 18 | |

| 40 | 1 1/2″ | 64 | 44 | 84 | 11.07 | 17.8 | 18.4 | |

| 50 | 2″ | 83 | 52 | 102 | 12.09 | 19 | 19.2 | |

| 65 | 2 1/2″ | 95 | 64 | 121 | 15.29 | 23.6 | 28.9 | |

| 80 | 3″ | 106 | 79 | 146 | 16.64 | 25.9 | 30.5 | |

| 100 | 4″ | 114 | 79 | 152 | 18.67 | 27.7 | 33 |