Haihao Group recently completed the delivery of a batch of DIN2605 304L 90° SMLS elbow pipe fittings to a valued client in the Netherlands. This batch, consisting of 160 high-precision elbows, underwent rigorous quality assurance procedures to ensure compliance with international standards and the client’s specific requirements.

DIN2605 304L 90° SMLS Elbows

Strict Quality Inspection

Prior to shipment, each elbow was meticulously inspected to confirm adherence to the following criteria:

Dimensional Accuracy: Comprehensive checks were conducted to verify the elbows’ outer diameter, wall thickness, bending radius, and beveling angles, ensuring a perfect fit during installation.

Quality inspection of DIN2605 304L 90° SMLS elbows

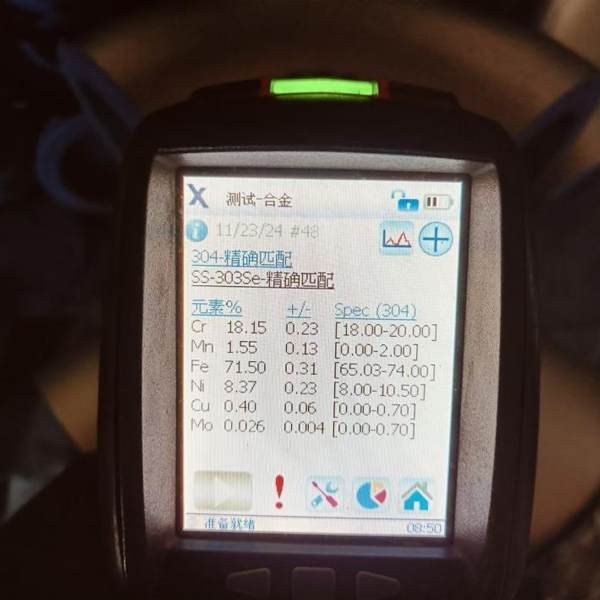

Chemical Composition Analysis: Samples from the batch were tested to confirm material consistency and compliance with the 304L stainless steel standard. The results were as follows:

| Chromium (Cr) | 18.15% (Requirement: 18%-20%) |

| Manganese (Mn) | 1.55% (Requirement: 1%-2%) |

| Iron (Fe) | 71.5% (Requirement: 65.03%-74%) |

| Nickel (Ni) | 8.37% (Requirement: 8%-10.5%) |

| Copper (Cu) | 0.4% (Requirement: 0%-0.7%) |

| Molybdenum (Mo) | 0.026% (Requirement: 0%-0.7%) |

All results confirmed full compliance with the specifications, ensuring the materials met the durability, corrosion resistance, and reliability required for industrial applications.

Quality inspection of DIN2605 304L 90° SMLS elbow

Packaging for Safe Transportation

To ensure the safe transportation of these elbows, Haihao Group utilized high-quality wooden crates for packaging. Each crate was designed to provide:

Protection Against Mechanical Damage: Preventing deformation or scratches during shipping.

Secure Positioning: Ensuring the elbows remained stable and intact throughout transit.

Environmental Safety: Using materials compliant with international shipping standards.

Commitment to Quality

This successful delivery underscores Haihao Group’s commitment to excellence in product manufacturing and quality control. Our rigorous approach to inspection and testing guarantees that our products meet the highest standards, ensuring reliability in critical pipeline applications.

With its superior quality and precision, the DIN2605 304L 90° SMLS elbow is a prime example of Haihao Group’s dedication to delivering world-class pipe fittings. Whether for oil and gas, petrochemicals, or other industrial sectors, our products are designed to meet and exceed customer expectations.

For more information about our products and services, please feel free to contact Haihao Group. Let us help you achieve success in your pipeline projects.Email:sales@haihaogroup.com