Steel pipe fittings are crucial components in various piping systems, connecting pipes and allowing for changes in direction, diameter, and flow. These fittings are made from different steel materials and produced using various manufacturing processes to meet the specific requirements of different applications.

Materials Used in Steel Pipe Fittings

ASTM A234 WPB Pipe Fittings

Carbon Steel

Common Grades: ASTM A105, ASTM A234 WPB

Properties: High strength, durability, and ability to withstand high pressure and temperature.

Applications: Widely used in oil and gas, petrochemical, and power generation industries.

ASME B16.9 A403 WP304L SMLS tees

Stainless Steel

Common Grades: ASTM A182 F304/304L, ASTM A182 F316/316L

Properties: Excellent corrosion resistance, high temperature tolerance, and good mechanical properties.

Applications: Used in chemical processing, food and beverage, pharmaceutical, and marine environments.

Alloy Steel

Common Grades: ASTM A182 F5, F9, F11, F22

Properties: Enhanced strength and corrosion resistance due to the addition of alloying elements like chromium, molybdenum, and nickel.

Applications: Ideal for high-temperature and high-pressure applications, such as in power plants and refineries.

Duplex and Super Duplex Stainless Steel

Common Grades: ASTM A182 F51, F53, F55

Properties: High strength, superior corrosion resistance, particularly against stress corrosion cracking.

Applications: Used in harsh environments such as offshore platforms, chemical processing, and seawater systems.

Low-Temperature Carbon Steel

Common Grades: ASTM A420 WPL6

Properties: Designed to retain toughness at low temperatures.

Applications: Used in cold climates and cryogenic systems.

Nickel Alloys

Common Grades: ASTM B366 Inconel 600, 625, Hastelloy C276

Properties: Exceptional resistance to high temperatures, corrosion, and oxidation.

Applications: Used in extreme environments such as chemical reactors and nuclear plants.

Before the production of an steel pipe fitting of a specific material,we should confirm the raw materia steel grade first,make sure the fittings from this raw material is absolutely as per the fittings materail technical requirements,such as the chemical composition,mechanical property,or the heat treatment data .

Production Processes for Steel Pipe Fittings

Forging Process:

The process involves heating a steel billet to a high temperature and then shaping it using a forging press or hammer.

The forging process enhances the grain structure of the steel, resulting in fittings with superior strength and durability.

Applications: This process is commonly used for the production of high-pressure fittings, including elbows, tees, reducers, and caps.

Machining Process:

Machining is a process that involves cutting and shaping a forged or rolled steel piece using lathes, milling machines, and drills in order to achieve precise dimensions and finishes.

This is typically used after forging or casting to achieve the final shape and specifications.

Applications: These products are used for precision components such as threaded fittings and flanges.

Casting Process:

The process involves pouring molten steel into a mould in order to shape the fitting. Once the casting has cooled and solidified, it is removed and finished.

Cast fittings can be produced in a variety of complex shapes and sizes.

Applications: This process is well-suited to fittings where high precision is less critical but large or complex shapes are needed, such as large valves or complex junctions.

Welding Process:

Welding processes, such as butt welding and socket welding, are employed to join sections of pipe and to fabricate pipe fittings from steel plates or sections.

Welding provides a robust and reliable solution for creating a leak-proof joint.

Applications: This process is commonly used in the fabrication of pipe spools, large reducers, and branch connections such as tees.

ASTM A182 F51 Pipe Fitting Forming

Hot Forming Process:

The steel is heated and then shaped using a die or roller, typically for the purpose of creating bends, elbows, or other curved fittings.

The hot forming process enables the production of fittings with smooth flow paths and uniform thickness, offering a highly efficient and effective solution for manufacturing precision-engineered components.

Applications: This process is used for the manufacture of elbows, tees and other shaped fittings.

Cold Forming Process:

The steel is shaped at room temperature, which can enhance its strength through strain hardening.

Cold forming is employed for the production of smaller fittings and when a high level of dimensional accuracy is required.

Applications: Often used to produce threaded fittings and small diameter components.

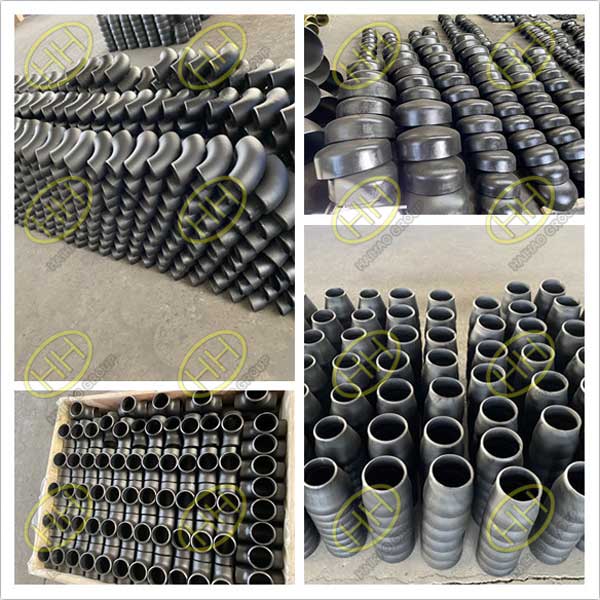

Hebei Haihao pipe fitting manufacture departments and technical engineers have rich experiments in the pipe fittings production.When we produce a new standard of steel fittings,we should check and confirm the raw material data carefully,and we will do experiments to test,finally we will do the finish products review and proof test.Then we can approve this pipe fittings materials and production process.Different kinds of pipe fittings standards have different technical requirements,we have professional skills in the pipe fitting production and development.With this ,we have confidence to serve our clients from different industry fields.