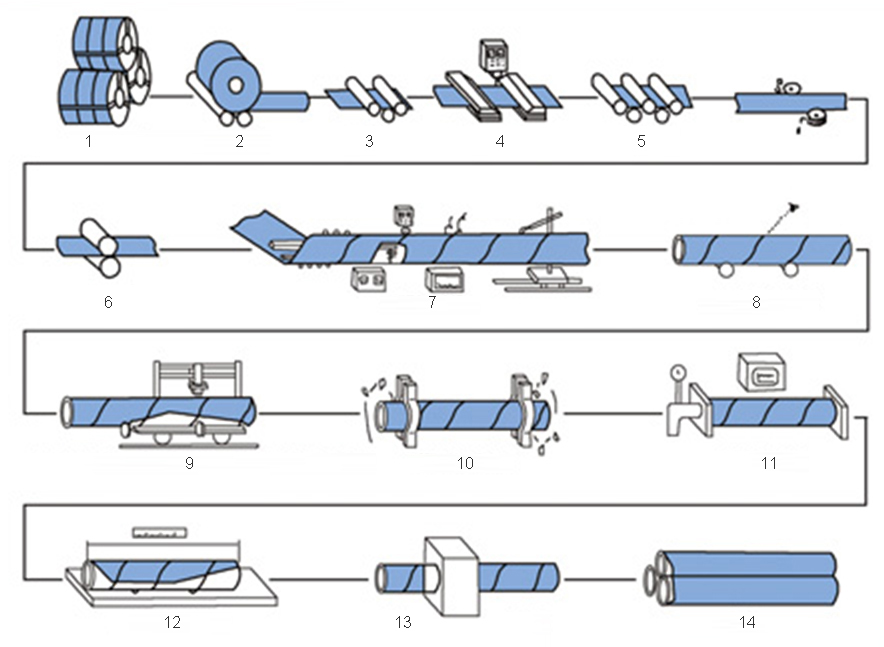

Spiral submerged arc welding (SSAW) is its forward direction and forming tube centerline hose reel molding angle (adjustable), side molding edge welding and weld them into a spiral.

As we know,seamless steel pipe always is small dimension,longitudinal submerge arc weld steel pipe is large dimension,but for larger dimension,we should use the method of spiral submerge arc welding instead of longitudinal submerge arc welding.With this method,we can use narrow width steel plates to produce large dimension pipes.The outside diameter is determined by the angle of the de-coiled steel against the forming head. In this welding process, the material is submerged under a bed of fusible flex, which becomes conductive when heated. The resulting weld is sound, uniform and corrosion resistant, with a deep weld penetration. It is a high-speed, automated process that is used for long straight welds and is effective for thin sheets of metal.