Socket Weld fittings General

A socket weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a valve, fitting or flange. In contrast to buttweld fittings, socket weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. To join pipe to valves and fittings or to other sections of pipe, fillet-type seal welds be used. Socket-welded joints construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations. Fatigue resistance is lower than that in butt-welded construction due to the use of fillet welds and abrupt fitting geometry, but it is still better than that of most mechanical joining methods.

Some details of Socket Weld fittings

SW Fittings are family of high pressure fittings are used in various industrial processes.

- They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

- They are used only in conjunction with ASME Pipe and are available in the same size range.

- They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

- They are are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical requirements, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

- They are available in three pressure ratings: Class 3000, 6000 and 9000.

Types of socket weld fittings by class, size and wall thickness

| Description | Class Designation | ||

| 3000 | 6000 | 9000 | |

| Elbows 45 and 90 degrees, Tees, Crosses, Couplings, Half-Couplings, End or Pipe Caps | 1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| Pipe Size by Wall Thickness | SCH 80 & XS | SCH 160 | XXS |

Plugs and Bushings are not identified. They may be used up through Class 6000 NPS

Forged Pipe Fittings Manufacturing Standards

ASTM A182-ASME SA182-Standard specification for wrought austenitic stainless steel piping fittings ASME B16.9- factory-made wrought butt welding fittings ASME B16.11-forged fittings,socket-welding and threaded MSS SP-43-wrought and fabricated butt-welding fittings for low pressure,corrosion resistant applications MSS SP-95- swage(d) nipples and Bull Plugs BS3799-specification for steel pipe fittings, screwed and socket-welding for the petroleum industry

Forged Socket Weld Stainless Steel Fittings

Stainless Steel – ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

- The material for forged stainless steel fittings conforms to ASME A182

- The dimensions for forged stainless steel fittings conform to ASME B16.11

Forged Socket Weld Carbon Steel Fittings

Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB

- The material for forged carbon steel fittings conforms to the requirements of ASTM/ASME A105/SA105 The dimensions for forged carbon steel fittings conform to ASME B16.11

Marking & Packing

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All forged fittings are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

Quality Assurance

At METLINE, all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products. Test Certificates: Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

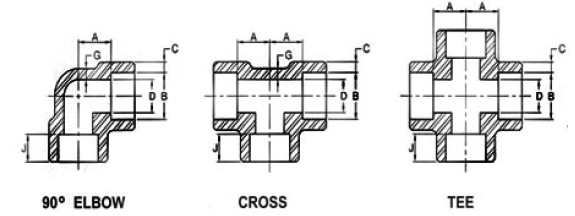

| Socket Weld 90°Elbow、Tee、Cross Dimensions | |||||||||

| Class | DN | NPS | A | B | D | C(Ave) | C(Min) | G | J |

| 3000 | 6 | 1/8″ | 11 | 10.8 | 6.9 | 3.18 | 3.18 | 2.41 | 9.5 |

| 8 | 1/4″ | 11 | 14.2 | 9.3 | 3.78 | 3.3 | 3.02 | 9.5 | |

| 10 | 3/8″ | 13.5 | 17.6 | 12.6 | 4.01 | 3.5 | 3.2 | 9.5 | |

| 15 | 1/2

“ |

15.5 | 21.8 | 15.8 | 4.67 | 4.09 | 3.73 | 9.5 | |

| 20 | 3/4″ | 19 | 27.2 | 21 | 4.9 | 4.27 | 3.91 | 12.5 | |

| 25 | 1″ | 22.5 | 33.9 | 26.7 | 5.69 | 4.98 | 4.55 | 12.5 | |

| 32 | 1 1/4″ | 27 | 42.7 | 35.1 | 6.07 | 5.28 | 4.85 | 12.5 | |

| 40 | 1 1/2″ | 32 | 48.8 | 40.9 | 6.35 | 5.54 | 5.08 | 12.5 | |

| 50 | 2″ | 38 | 61.2 | 52.5 | 6.93 | 6.04 | 5.54 | 16 | |

| 65 | 2 1/2″ | 41 | 73.9 | 62.7 | 8.76 | 7.67 | 7.01 | 16 | |

| 80 | 3″ | 57 | 89.8 | 78 | 9.52 | 8.3 | 7.62 | 16 | |

| 100 | 4″ | 66.5 | 115.2 | 102.3 | 10.69 | 9.35 | 8.56 | 19 | |

| 6000 | 6 | 1/8″ | 11 | 10.8 | 4 | 3.96 | 3.43 | 3.15 | 9.5 |

| 8 | 1/4″ | 13.5 | 14.2 | 6.4 | 4.6 | 4.01 | 3.68 | 9.5 | |

| 10 | 3/8″ | 15.5 | 17.6 | 9.2 | 5.03 | 4.37 | 4.01 | 9.5 | |

| 15 | 1/2″ | 19 | 21.8 | 11.8 | 5.97 | 8.18 | 4.78 | 9.5 | |

| 20 | 3/4″ | 22.5 | 27.2 | 15.6 | 6.96 | 8.56 | 5.56 | 12.5 | |

| 25 | 1″ | 27 | 33.9 | 20.7 | 7.92 | 9.96 | 6.35 | 12.5 | |

| 32 | 1 1/4″ | 32 | 42.7 | 29.5 | 7.92 | 10.62 | 6.35 | 12.5 | |

| 40 | 1 1/2″ | 38 | 48.8 | 34 | 8.92 | 11.12 | 7.14 | 12.5 | |

| 50 | 2″ | 41 | 61.2 | 42.9 | 10.92 | 12.12 | 8.74 | 16 | |

| 65 | 2 1/2″ | – | 73.9 | – | – | – | – | 16 | |

| 80 | 3″ | – | 89.8 | – | – | – | – | 16 | |

| 100 | 4″ | – | 115.2 | – | – | – | – | 19 | |

| 9000 | 6 | 1/8″ | – | 10.8 | – | – | – | – | 9.5 |

| 8 | 1/4″ | – | 14.2 | – | – | – | – | 9.5 | |

| 10 | 3/8″ | – | 17.6 | – | – | – | – | 9.5 | |

| 15 | 1/2″ | 25.5 | 21.8 | 6.4 | 9.35 | 5.18 | 7.47 | 9.5 | |

| 20 | 3/4″ | 28.5 | 27.2 | 11.1 | 9.78 | 6.04 | 7.82 | 12.5 | |

| 25 | 1″ | 32 | 33.9 | 15.2 | 11.38 | 6.93 | 9.09 | 12.5 | |

| 32 | 1 1/4″ | 35 | 42.7 | 22.8 | 12.14 | 6.93 | 9.7 | 12.5 | |

| 40 | 1 1/2″ | 38 | 48.8 | 28 | 12.7 | 7.8 | 10.15 | 12.5 | |

| 50 | 2″ | 54 | 61.2 | 38.2 | 13.84 | 9.5 | 11.07 | 16 | |

| 65 | 2 1/2″ | – | 73.9 | – | – | – | – | 16 | |

| 80 | 3″ | – | 89.8 | – | – | – | – | 16 | |

| 100 | 4″ | – | 115.2 | – | – | – | – | 19 | |