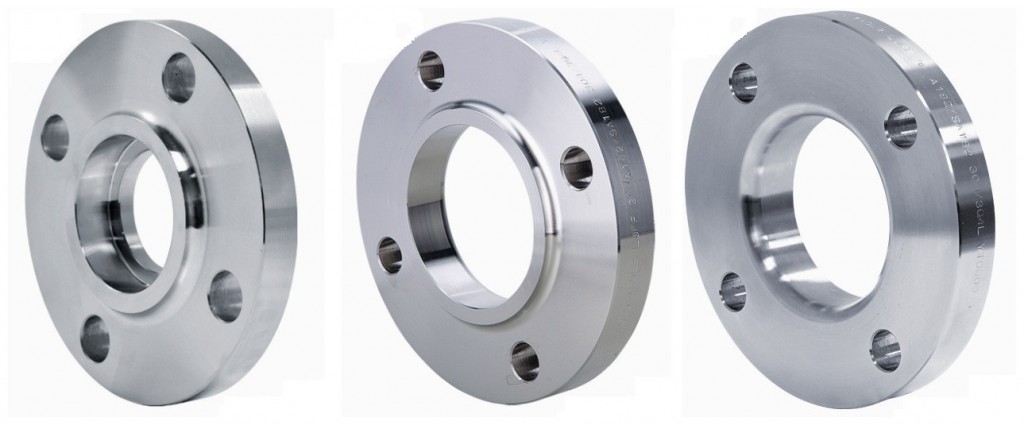

Socket Welding Neck Flange

Definition and Details of Socket Weld Flange:

Socket weld flanges were initially developed for use on small-size high pressure piping. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Assembly says:

In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16″ (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.

Advantages of Socket Weld Flange :

The disadvantage of this flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes this flange is also not allowed. I am not an expert in this matter, but on the internet, you will find a lot of information about forms of corrosion.

Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to reface the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping.

Socket Weld Flange Welded to Pipe :

1. Socket Weld flange 2. Filled weld 3. Pipe

X = Expansion gap

Socket weld flange VS Lap Joint Flange & Slip On Flange:

A lap joint flange is very similar to a slip-on flange, with the main difference being that it has a curved radius at the bore and face to house a lap joint stub-end. Lap joint flanges and stub-end assemblies are typically used in situations where frequent dismantling is required for for inspection.

Socket weld flanges are similar to slip-on flanges, however, socket welds have an internal recess on the inside diameter to allow for a smoother flow of the process fluid. The positive of this is that is creates a smooth bore with the proper welding and grinding. The negative of this type of flange is that it can be more expensive than a slip-on due to more intricate machining, and they can be less readily available than slip-ons due to the fact that the bottom half of the inside diameter must be made to the same schedule as the pipe that is being used. (you must specify the schedule needed) These socket weld flanges were initially developed for use on smaller sizes of pipe at higher pressure ratings. They are more used on lower pressure temperature as well today.