Haihao Group is pleased to announce a significant order from our esteemed client in Singapore for the ASME B36.10 ASTM A333-P5 SCH80 6 meter SMLS pipes. This order underscores our commitment to delivering high-quality products tailored to meet the specific needs of our global clientele.

A seamless steel pipe, as the name suggests, is a pipe that does not have any seams or weld joints. Unlike welded pipes, which are made by rolling and welding a sheet of steel, seamless pipes are made from solid steel billets that are heated and then stretched over a form until the steel is shaped into a hollow tube. This method of production gives seamless pipes superior strength and durability, making them ideal for high-pressure applications.

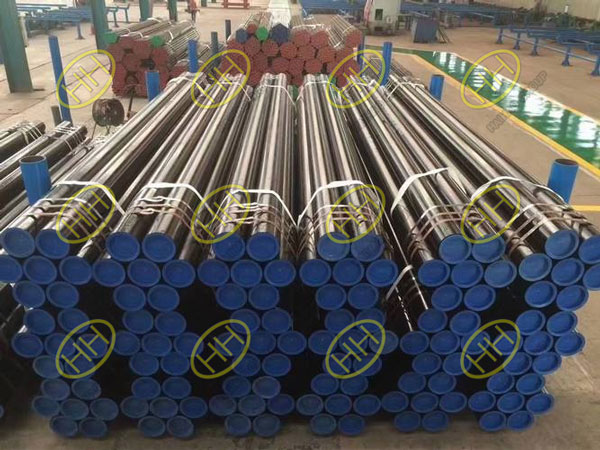

ASME B36.10 ASTM A333 P5 SCH80 6 meter SMLS pipes

Differences Between Seamless and Welded Steel Pipes

- Manufacturing Process:

Seamless Pipes: Produced by extruding the metal to the desired length; hence, there are no joints in the pipe.

Welded Pipes: Made by rolling metal and welding it longitudinally across its length.

- Strength and Durability:

Seamless Pipes: Generally stronger and more reliable due to the absence of welds. This makes them suitable for high-pressure applications.

Welded Pipes: Though strong, they may have a weak point at the weld seam, which can be a potential source of failure under high pressure or stress.

- Surface Quality and Appearance:

Seamless Pipes: Typically have a uniform structure and better surface quality.

Welded Pipes: May have visible welds and require additional finishing to match the surface quality of seamless pipes.

Advantages of ASTM A333-P5 Material

The ASTM A333-P5 material is specifically designed for low-temperature service. It provides several key advantages:

- Low-Temperature Performance:

High Toughness: The material maintains high toughness even at low temperatures, ensuring reliability and safety in cryogenic conditions.

Good Impact Resistance: Excellent impact resistance minimizes the risk of fractures under low-temperature conditions.

- High Strength:

Superior Mechanical Properties: The material offers high tensile and yield strength, which makes it suitable for use in high-stress environments.

- Corrosion Resistance:

Enhanced Durability: The composition of ASTM A333-P5 provides resistance to corrosion, ensuring a longer lifespan for the pipes even in harsh environments.

Our Commitment to Quality

At Haihao Group, we ensure that all our products meet the highest standards of quality and performance. The ASME B36.10 ASTM A333-P5 SCH80 6 meter SMLS pipes are no exception. Each pipe undergoes rigorous testing and quality checks to ensure it meets our stringent specifications and the specific requirements of our customers.

We are proud to serve our Singapore customer with our high-quality seamless pipes, ensuring they receive products that are robust, reliable, and fit for their demanding applications. Haihao Group remains dedicated to innovation, quality, and customer satisfaction. We look forward to continuing our partnership and providing exceptional piping solutions for projects around the world.

For more information about our products and services, please contact us. Haihao Group is here to meet your every piping need with excellence and precision.