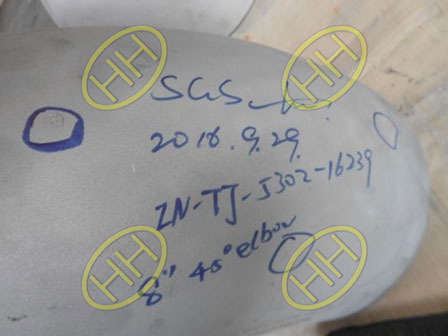

Septermber 29th,inspector from SGS carried out the third party inspection to our stainless steel butt welding pipe fittings in Haihao Pipe Fitting Factory before shipment.

SGS Inspector Tested Our A403 WP321 Elbows

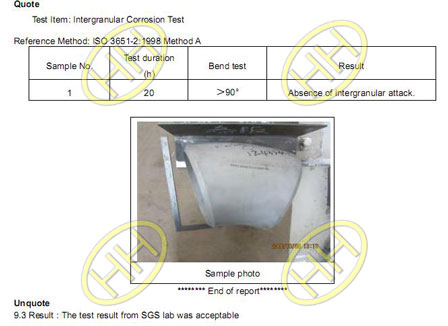

These pipe fittings will be used in high pressure condition,so clients required many strictly inspections.Besides the regular check such as,quantity check,packing check,marking check,dimensions testing and PMI testing according to ASME B16.9,the SGS laboratory also arranged the intergranular corrosion testing.(What is intergranular corrosion in metal material?)

Haihao Stainless Steel Elbows Under Intergranular Corrosion Testing In SGS Lab

Our ASTM A403 WP321 elbows was soaked into acid solutions for 20 hours,then bended the soaked elbows to check the intergranular attack situation.The testing is carried out as per ISO 3651 standard and the test result our pipe fittings from SGS lab are acceptable.(The standards and methods for intergranular corrosion test)

Elbow Samples For SGS Inspection From Our Fittings Order