The hot-extrusion process consists of enclosing a piece of metal, heated to forging temperature, in a chamber called a “container” having a die at one end with an opening of the shape of the desired finished section, and applying pressure to the metal through the opposite end of the container. The metal is forced through the opening, the shape of which it assumes in cross-section, as the metal flows plastically under the great pressures used.

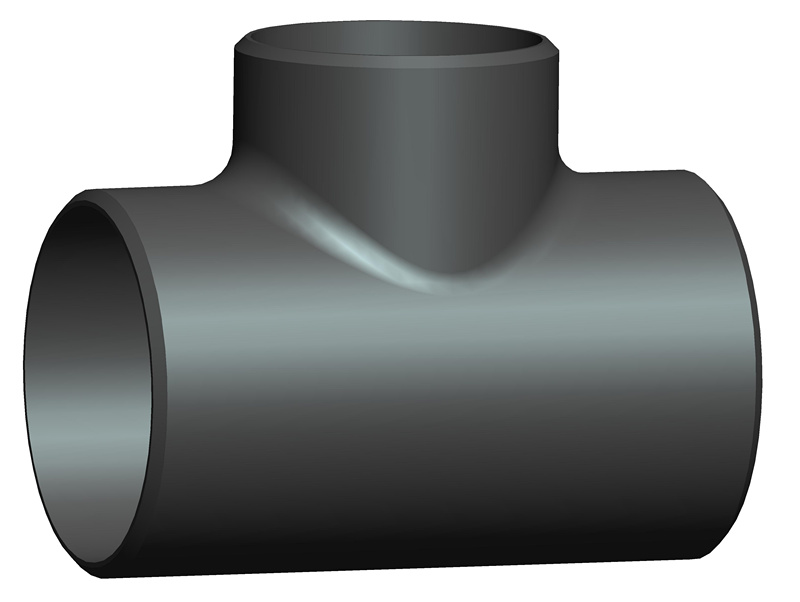

Tees using raw material with a bigger diameter than the finished product, the branch outlet is extruded from pipe while the main body is being pressed. The outlet’s wall thickness can also be adjusted as needed. Applied to tees with large diameters, heavy wall thickness and/or special material with challenging workability that cannot be manufactured using the hydraulic bulge method.

[topswf swf=’https://www.haihaopiping.com/wp-content/uploads/2015/10/Seamless-Tee-Made-by-Hot-drawing-Forming.swf’ width=’655′ height=’400′ quality=’best’ wmode=’transparent’ scale=’default’ flashvars=” allowfullscreen=’false’]