When it comes to critical applications in petrochemical plants, offshore platforms, and high-pressure pipelines, the quality of pipe fittings is not just a specification—it’s a matter of safety, performance, and long-term reliability. To ensure that each fitting meets international standards and project requirements, manufacturers provide a comprehensive set of quality documentation. Among the most essential of these are the Material Test Certificate (MTC), Non-Destructive Testing (NDT) reports, and Impact Test results.

In this article, we’ll explore what these reports mean, why they matter, and how Haihao Group ensures that every fitting it delivers is backed by traceable and verifiable quality data.

XRF PMI testing method of ASTM A403 WP304 material pipe fittings

What is an MTC and why is it important?

An MTC (Material Test Certificate), also known as a mill test certificate, provides full traceability and chemical-mechanical property verification for raw materials used in manufacturing pipe fittings. Issued in accordance with international standards such as EN 10204 3.1 or 3.2, an MTC includes:

- Chemical composition analysis

- Mechanical properties (yield strength, tensile strength, elongation, etc.)

- Heat treatment records

- Material grade and heat number

- Manufacturing process and traceability

For engineers and procurement professionals, the MTC is a critical document to confirm that the pipe fittings conform to the required ASTM, ASME, or API standards. It serves as the first checkpoint for material quality and compliance—particularly in sour service or high-pressure systems.

Magnetic particle testing for large diameter elbow welds

NDT: Non-Destructive Testing for Hidden Flaws

Even if a fitting meets all dimensional and material standards, internal defects such as cracks, inclusions, or porosity can jeopardize system integrity. This is where Non-Destructive Testing (NDT) plays a vital role.

At Haihao Group, all critical fittings undergo NDT procedures such as:

- Ultrasonic Testing (UT): Used to detect internal flaws and wall thickness variations

- Radiographic Testing (RT): Provides X-ray images to reveal hidden defects in welds or material structure

- Magnetic Particle Inspection (MPI) and Dye Penetrant Testing (DPT): Surface testing methods for detecting surface cracks or discontinuities

These tests are especially crucial in offshore environments, chemical processing plants, and oil & gas pipelines, where a single failure could lead to environmental damage, safety hazards, or costly shutdowns.

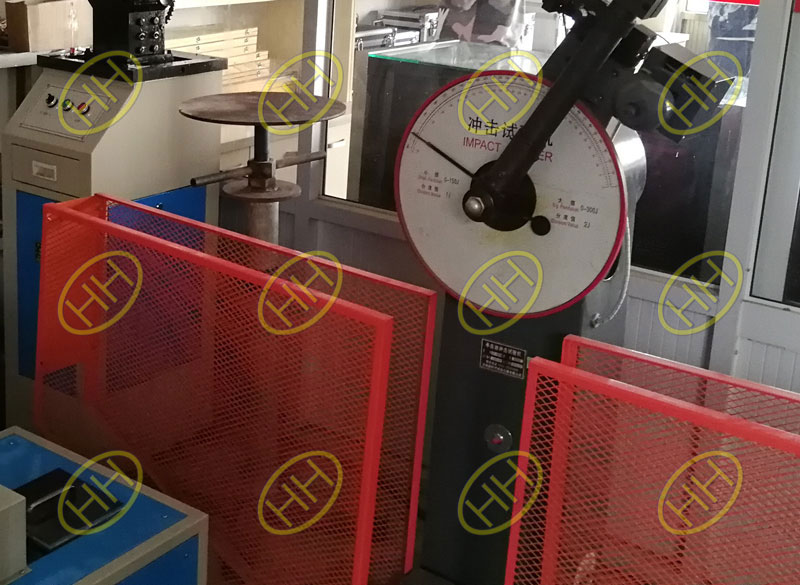

Impact test in Haihao Group

Impact Test: Verifying Toughness at Low Temperatures

In industries like LNG, offshore oil platforms, or arctic installations, pipe fittings must withstand extremely low temperatures without becoming brittle. That’s why the impact test, particularly the Charpy V-Notch test, is performed to evaluate a material’s toughness.

This test helps determine whether a fitting can absorb energy and resist fracture under sudden impact loads at low temperatures. Haihao provides certified impact test reports according to standard requirements (such as -46°C or -50°C testing), ensuring suitability for harsh environments.

MSS SP-95 ASTM A815 UNS S32760 concentric swage nipple

Dimensional Reports: Ensuring Accurate Fit and Installation

In addition to material integrity, accurate dimensions are essential for system compatibility and smooth installation. Each fitting produced by Haihao Group is checked against ASME, MSS, or DIN standards, and a dimensional report is provided to verify:

- Outer and inner diameters

- Wall thickness

- Socket depth or thread engagement

- Bending angles and center-to-end lengths

These dimensional checks prevent issues like mismatched fittings, leakages, or misalignment during on-site installation.

Haihao Group’s Commitment to Quality Assurance

At Haihao Group, we believe that quality is not just promised—it is proven. Every fitting we supply is accompanied by a full set of inspection and testing documentation, including:

- MTCs that confirm material grade and compliance

- NDT reports validating internal and external integrity

- Impact test results for temperature resilience

- Dimensional inspection reports to ensure perfect fit

For projects in the petrochemical, marine, and energy sectors, our documentation not only ensures compliance—it provides peace of mind.

Understanding the value of an MTC, NDT, and impact test report can help project engineers and procurement teams make better decisions when sourcing pipe fittings. These reports are more than paperwork—they are the foundation of trust between supplier and end user.

Whether you’re building an offshore platform in the UAE or installing high-pressure pipelines in a refinery, choosing a partner like Haihao Group, who delivers both high-quality products and full transparency, ensures the success and safety of your system. Email:sales@haihaogroup.com