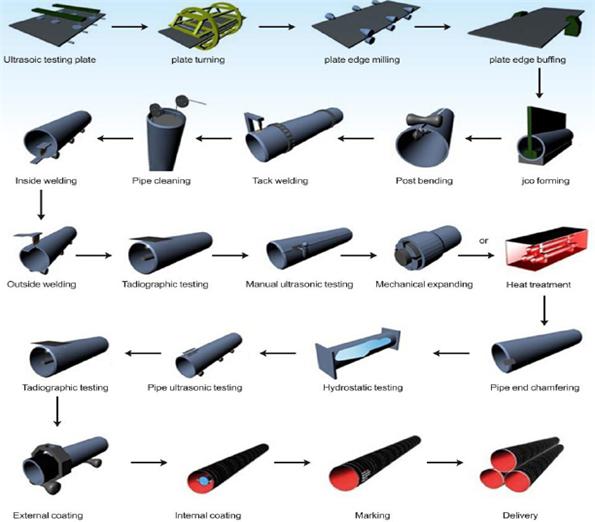

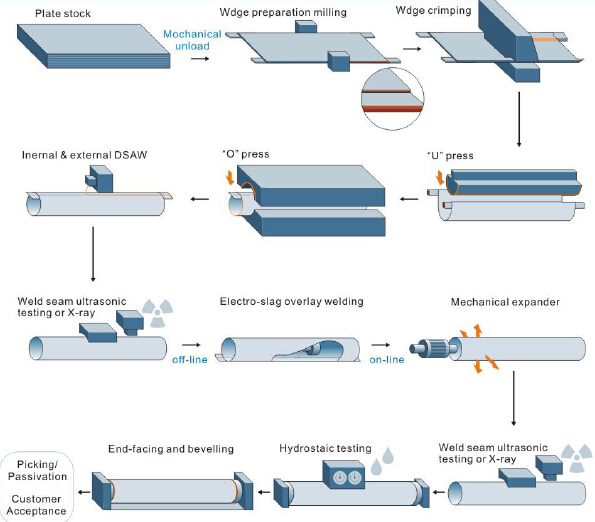

Longitudinal-seam Submerged Arc Welded (LSAW) pipes were made of steel plates cut from leveled hot rolled coils by both the JCOE and UOE (the forming process in which the plate like the letter “J”, “C”, “O” or “U” shape, then expansion) forming processes. Furthermore, the mechanical properties of the pipe base metal and weld metal were tested, and the results were in accordance with the corresponding pipe specification API SPEC 5L or DNV-OS-F101, which showed that domestic LSAW pipes could be used for oil and gas pipelines.

Longitudinal-seam Submerged Arc Welded (LSAW) pipes with JCOE Process and UOE Process :

1.Manufacture: For Large-diameter(25 centimetres (10 in) or greater) pipe, usually used ERW(Electric resistance welding),EFW(Electric fusion welding) or Submerged Arc Welded(SAW),but there are tow technologies,with these we can manufacture larger size pipes than seamless and ERW process!They are Longitudinal submerged arc welded (LSAW) and Spiral submerged arc welded (SSAW) pipes. Longitudinal submerged arc welded (LSAW) pipes manufacture process is bending and welding wide steel plates to pipes.Most commonly used in oil and gas industry application in low pressure. Inspection: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test. Application of LSAW Steel Pipe The tubes are mainly used for oil, natural gas, gas, central heating, water supply, sewage treatment, low-pressure fluid delivery and so on.

The material of LSAW steel pipe is unit middle or heavy thickness sheet,coiled in the molding or forming machine, welded by double submerged arc welding and expand the diameter.the specification scope is wide,and have good toughness, ductility, uniformity, compactness. Advantage of LSAW steel pipe the difference with SSAW steel pipe: Diameter large,heavy wall thickness,anti-high pressure,anti-low temperature and corrosion.