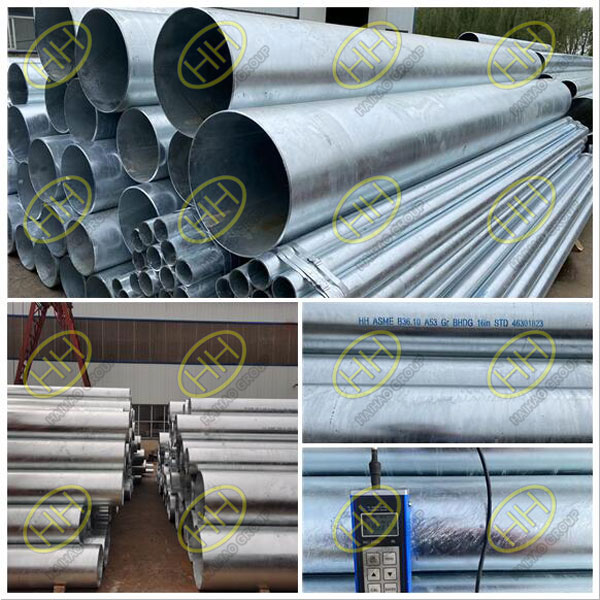

Hot dip galvanized pipe is to make molten metal react with iron matrix to produce alloy layer, so as to combine the matrix and coating. Hot dip galvanizing is to pickle the steel pipe first. In order to remove iron oxide on the surface of the steel pipe, after pickling, it is cleaned in ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent to the hot dip galvanizing tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. The matrix of hot-dip galvanized steel pipe reacts with the molten bath in a complex physical and chemical way to form a corrosion-resistant Zn Fe alloy layer with compact structure. The alloy layer is integrated with pure zinc layer and steel pipe matrix, so it has strong corrosion resistance.

Hot dip galvanized steel pipes

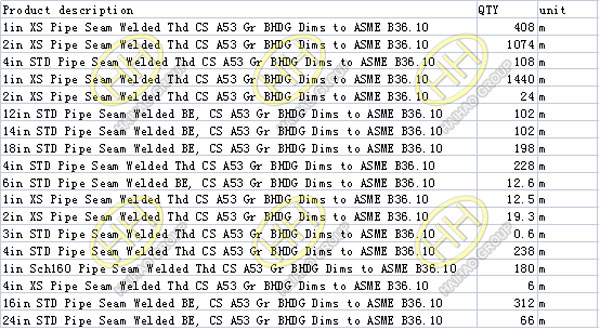

Do you remember the hot-dip galvanized pipe fittings exported to Romania last time? After receiving the goods, the customer felt very good and purchased a batch of hot-dip galvanized steel pipes from us. The list is as follows.

Hot dip galvanized steel pipe list

At present, the thickness of zinc coating has been tested and ready for delivery,If you need galvanized steel pipe, please contact us.