In industries where reliability and durability are paramount, Super Duplex Stainless Steel ASTM A182 GR. F55 has established itself as a material of choice. Its unique combination of chemical composition, mechanical properties, and superior corrosion resistance makes it ideal for the most demanding environments. This article delves into the strengths of ASTM A182 GR. F55 and why it stands out in industrial applications.

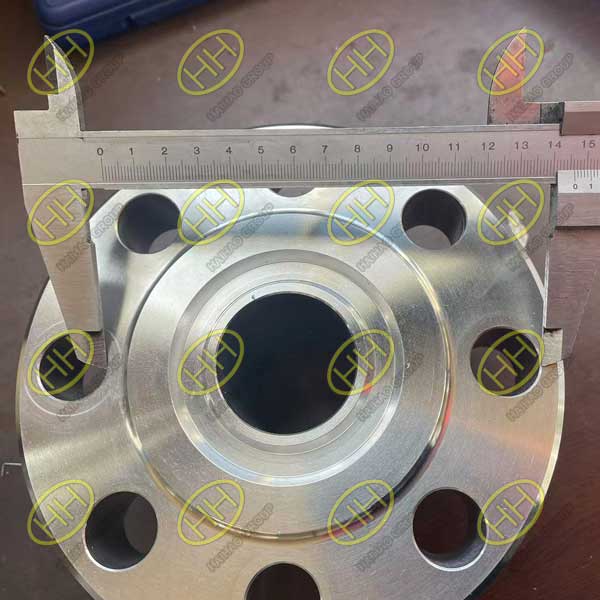

API 6A TYPE 6BX ASTM A182 GR. F55 flange

Material Analysis: The Chemistry Behind Excellence

Super Duplex Stainless Steel ASTM A182 GR. F55 owes its outstanding properties to its carefully balanced chemical composition. Key elements include:

High Chromium (Cr) Content (24–26%): Provides exceptional resistance to general corrosion and stress corrosion cracking, even in harsh environments like seawater or acidic conditions.

High Molybdenum (Mo) Content (3–5%): Enhances resistance to pitting and crevice corrosion, making it ideal for environments prone to localized attack.

Nickel (Ni) and Nitrogen (N): Strengthen the microstructure and improve mechanical properties, ensuring high yield and tensile strength.

This combination of elements enables F55 to exhibit dual-phase characteristics, offering the benefits of both austenitic and ferritic stainless steels. The result is a material with exceptional durability, resistance to fatigue, and unmatched corrosion resistance.

Technical Challenges: Machining Super Duplex Stainless Steel

While ASTM A182 GR. F55 offers remarkable performance, its processing presents unique challenges due to its high strength and hardness. Key machining considerations include:

Tool Wear: The material’s hardness increases wear on cutting tools, requiring the use of carbide or coated tools with proper cooling.

Heat Generation: High cutting forces during machining can generate significant heat, which must be managed to prevent thermal damage to the material.

Precision Requirements: Given its applications in critical industries, machining tolerances are stringent, demanding advanced techniques like CNC machining.

At Haihao Group, our experienced technicians and state-of-the-art equipment ensure precision and quality during the machining of F55 components, meeting even the most demanding specifications.

Quality inspection of API 6A TYPE 6BX API 6A TYPE 6BX ASTM A182 GR. F55 flange flange

Industry Comparison: F55 vs. Other Common Materials

When compared to traditional materials like ASTM A105 (carbon steel) or 316 stainless steel, ASTM A182 GR. F55 demonstrates clear advantages:

| Property | ASTM A182 GR. F55 | ASTM A105 (Carbon Steel) | 316 Stainless Steel |

| Corrosion Resistance | Excellent (even in seawater) | Low (prone to rust) | Good, but susceptible to pitting in chlorides |

| Yield Strength | ~550 MPa | ~250 MPa | ~290 MPa |

| Pitting Resistance | Outstanding (PREN > 40) | Not applicable | Moderate (PREN ~ 25) |

This comparison highlights the superiority of F55 in environments requiring high corrosion resistance and strength, such as offshore platforms, chemical processing, and desalination plants.

Super duplex stainless steel ASTM A182 GR. F55 is a testament to the advancements in metallurgy, offering unparalleled corrosion resistance, mechanical strength, and durability. Despite its processing challenges, its performance advantages make it an essential material for industries operating in extreme environments. At Haihao Group, we combine technical expertise and cutting-edge technology to deliver F55 products that exceed customer expectations, ensuring safety and efficiency in every application. Email:sales@haihaogroup.com