Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape.Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material.Initially this manufacturing process used low frequency A.C. current to heat the edges. This low frequency process was used from the 1920’s until 1970. In 1970, the low frequency process was superseded by a high frequency ERW process which produced a higher quality weld. Over time, the welds of low frequency ERW pipe was found to be susceptible to selective seam corrosion, hook cracks, and inadequate bonding of the seams, so low frequency ERW is no longer used to manufacture pipe. The high frequency process is still being used to manufacture pipe for use in new pipeline construction.

Electric resistance welding can be divided into two kinds:resistance welding and induction welding.ERW pipe is cold formed into a cylindrical shape rather than hot formed. An electric current rather than a flame is used to heat the edges of the strip for the fusion weld. Revolving copper discs serve as electrodes and raise the temperature to about 2600°F for effective welding. Different from longitudinally Submerged Arc Welding,Usually ERW uses AC with frequency from 100 to 800 kHz, or 100.000 to 800.000 cycles per second.

This process is characterized by two effects: skin effect, or concentration of high-frequency current on the surface,and proximity effect when a high-frequency concentrates on the two adjacent parallel inner edges in the welded wedge, before the welding point. These effects allow a welding process to take place with the least amount of heat released, and because of that the structure of the basic material changes in a relative small zone around the central – ferit line of welds. Scavenging melted material from inner and outer side of the weld is removed by scraping devices.

Electric resistance welded (ERW) pipe manufacturing process

While manufacturing ERW steel pipes,only high-quality, continuous-cast, fully killed, control-rolled, fine-grain, low-carbon steel is used. High performance ERW steel pipes and tubing possess high strength corrosion resistance, high deformability, high strength and high toughness. We are among the leading manufacturers and suppliers of erw pipes and tubes in China. We are also one of the largest exporters of ERW pipes and tubes in China.

ERW pipes and tubes stands for Electric Resistance Welded pipes and tubes. Based on the customers requirements we can manufacture erw pipes and tubes of different size and shape. We have a very large production capacity of erw pipes and tubes. ERW pipes and tubes are used in various engineering purposes, fencing, scaffolding, line pipes etc. ERW pipe is available in lengths from single random to 120 feet depending on mill capability.

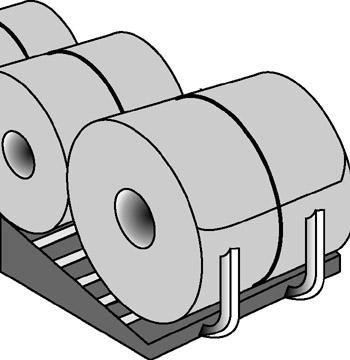

ERW pipe is available with square ends or beveled for welding, threaded and coupled and victaulic grooved. Surface finish are available in black or bare, or with protective coatings. For pipes or tubes size 4 inch (10.2mm) OD and below, strip is fed into a set of forming rolls which consists of horizontal and vertical rollers so placed as to gradually from the flat strip in to a tube which is then allowed to pass the welding electrodes. The electrodes are copper disks connected to the secondary of a revolving transformer assembly. Coil Feed Ramp The coils are removed from storage and placed on the feed ramp (see Figure 4.1). Each coil is fed into the uncoiling unit.

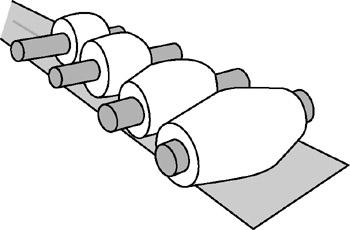

Figure 4.2: First Forming Section Final Forming Pass Section This section of the forming rolls finishes the rounding process and prepares the edges of the strip for welding (see Figure 4.3).

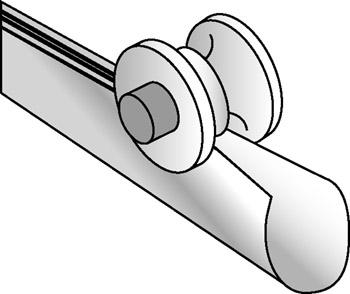

Figure 4.3: Final Forming Pass Section High-Frequency Welder An automatic high-frequency welder heats the edges of the strip to approximately 2600 F at the fusion point location (see Figure 4.4). Pressure rollers squeeze these heated edges together to form a fusion weld.

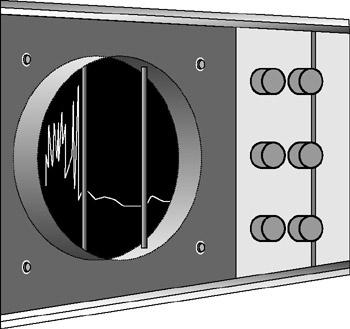

Figure 4.4: Automatic High-Frequency Welder In-Process Weld Nondestructive Inspection After welding has been completed, it is inspected by independent nondestructive inspection units (see Figure 4.5).

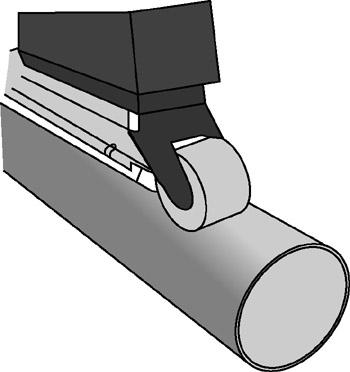

Figure 4.5: Nondestructive Inspection Unit Seam Weld Normalizing The weld area is then subjected to postweld treatment, as metallur-gically required, to remove residual welding stresses and produce a uniform normalized grain structure (see Figure 4.6).

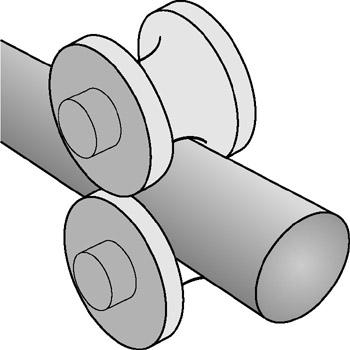

Figure 4.6: Seam Weld Normalizer Sizing Mill The pipe passes through a sizing mill to achieve the correct outside diameter (see Figure 4.7).

Figure 4.7: Sizing Mill Cutting the Pipe