Haihao Group recently completed an order for our Singaporean client, producing ASME B36.10 A53 GR.B ERW pipe and ASME B36.10 A53 GR.B LSAW pipe. These two types of pipes, while both conforming to ASTM A53 GR.B material specifications, differ in their manufacturing processes, structure, and application suitability. Understanding these differences is essential for selecting the right pipe for specific applications.

1.Manufacturing Process: ERW vs. LSAW

A53 GR.B ERW (Electric Resistance Welded) Pipe:

The ERW pipe is produced by rolling steel coils into a tube shape and then using electric resistance welding to join the edges together. The welding process involves passing an electrical current through the edges of the metal, causing the edges to heat up and form a bond. This is a high-speed process that is commonly used for small-diameter pipes and is cost-effective for large-scale production.

A53 GR.B LSAW (Longitudinal Submerged Arc Welded) Pipe:

The LSAW pipe is manufactured using a longitudinal welding process, where the steel plate is bent into a pipe shape and then welded along its length using a submerged arc welding process. This process allows for larger-diameter pipes and provides a stronger weld, making it ideal for high-pressure applications.

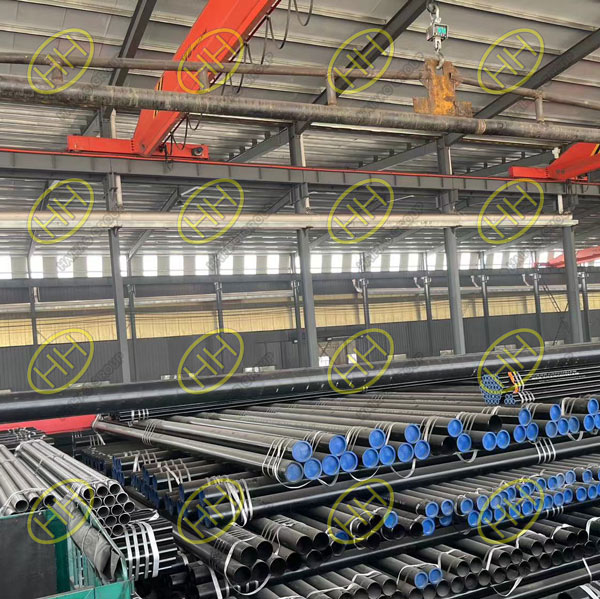

ASME B36.10 ASTM A53 GR.B BE ERW pipes

2.Pipe Structure and Strength

A53 GR.B ERW Pipe:

ERW pipes are generally suited for low to medium-pressure applications. The welded seam is typically less robust than that of LSAW pipes, and while it offers good corrosion resistance and strength, it is not as suitable for extreme pressure or highly demanding environments as LSAW pipes.

A53 GR.B LSAW Pipe:

LSAW pipes have a longitudinal weld along the length of the pipe, which provides a stronger and more durable bond. This makes LSAW pipes ideal for high-pressure systems and larger diameter piping applications. Due to the higher strength of the weld, LSAW pipes are used in more critical and heavy-duty applications, such as oil and gas pipelines and large-diameter transmission lines.

3.Applications

A53 GR.B ERW Pipe:

Typically used in low to medium-pressure systems, ERW pipes are widely used for water pipelines, gas transmission, and construction. They are cost-effective and suitable for smaller-diameter pipes and non-critical applications where the strength requirements are lower.

A53 GR.B LSAW Pipe:

LSAW pipes are primarily used in high-pressure applications like oil and gas pipelines, offshore drilling, and large-scale infrastructure projects. They are also preferred for large-diameter pipe systems that require stronger structural integrity.

Longitudinal seam Submerged Arc Welded (LSAW) pipes

4.Cost Considerations

A53 GR.B ERW Pipe:

ERW pipes are typically more affordable compared to LSAW pipes due to the simpler manufacturing process. They offer a good balance between performance and cost, making them a popular choice for a wide range of industries.

A53 GR.B LSAW Pipe:

LSAW pipes are generally more expensive than ERW pipes due to the more complex manufacturing process and the increased strength and durability of the welded seam. However, their superior performance makes them worth the investment for high-demand applications.

Both ASME B36.10 A53 GR.B ERW pipe and ASME B36.10 A53 GR.B LSAW pipe meet ASTM A53 GR.B standards, but they differ significantly in terms of their manufacturing processes, strength, and suitability for various applications. ERW pipes are ideal for low to medium-pressure applications, while LSAW pipes are better suited for high-pressure systems and large-diameter pipelines.

At Haihao Group, we ensure the highest quality and precision in manufacturing both types of pipes, meeting the specific requirements of our clients. For more information or to place an order, contact Haihao Group today! Email:sales@haihaogroup.com