There are various connecting types for the steel pipes,pipe fittings and flanges: socket weld,butt weld,threaded and so on.Socket welding and butt welding are the quite popular of those.However,you might be confused about which one would be best for your pipeline system,since both of them seem to have their own pros and cons.Therefor,we have taken the responsibility of drawing up a comparison between them.

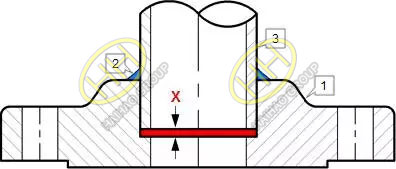

flange socket welding with pipe fitting picture

1.socket weld flanges 2.socket welding seams 3.pipelines X equals gaps of welding seams

Socket welding refers to the pipe into the valve body for welding,mostly used for 2″ below the carbon steel pipe, stainless steel pipe welding.

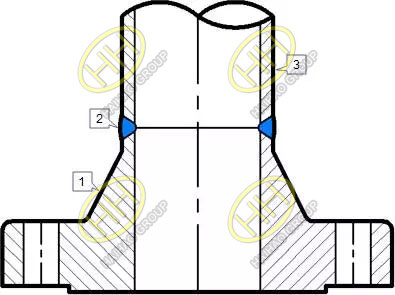

flange butt welding with steel pipe picture1.

1.butt weld flanges 2.butt welding seams 3.pipes or pipe fittings

Butt welding refers to the use of resistance heat along the whole face of the two workpieces together at the same time welding,is widely used in the workpiece welding.

There is the difference between socket welding and butt welding in pipeline system:

- Socket welding forms a fillet weld,while butt welding forms a butt weld. Butt welding is superior to socket welding in strength and stress condition, so it is appropriate to use butt welding in occasions with high pressure grade and poor service condition.

- Socket welding is generally used for small pipe diameter less than or equal to DN40, such as small diameter valve and pipe,pipe fittings and pipe welding, more economical, butt welding is generally used for DN40 above.

- Socket welding is mostly used for those with low pressure grade and small diameter, while butt welding is often used for those with high pressure grade. In addition, 100% flaw detection test is required for welding to ensure no leakage.

- Socket welding requires different diameters to be inserted for welding, but there is no requirement for butt welding.

- Butt welding requirements are generally higher than socket welding requirements, welding quality is good, so the detection method is relatively strict. X-ray inspection is required for welding,while magnetic powder or penetration detection is required for socket welding (such as magnetic powder for carbon steel and penetration for stainless steel).

Flange butt welding with steel pipes finished in Haihao Group

Haihao Group has been producing butt welding and socket welding pipeline products for a variety of applications since 1982,our products contain steel pipes(seamless steel pipes,API 5L line pipe,welded pipe,galvanized pipe,oil casting pipe,boiler tube,precision steel pipe,coated and insulated piping),pipe fittings(pipe elbow,tee,reducer,cap,bend,coupling,nipple,cross etc) and flanges(weld neck flange,blind flange,socket weld flange,threaded flange,slip on flange,lap joint flange,orifice flange,spectacle flange,anchor flange,reducing flange,tube sheet,flange-olet etc).

Please feel free to contact us,Email:sales@haihaogroup.com