Cold-drawn steel pipe generally takes several times pulling in between each drawing a corresponding stress relieving, to ensure the smooth progress of the next cold drawn.

From the appearance of cold-rolled seamless steel tubes tend to be small in diameter, hot-rolled seamless steel tubes are often large diameter. Cold-rolled precision seamless steel tube is higher than hot-rolled seamless steel tubes, the price is also higher than hot-rolled seamless steel tubes. Cold Drawn Seamless normal-caliber small, mostly in the 127mm below, especially in cold-drawn seamless tube outer diameter accuracy is very high, cold drawn seamless pipe lengths are generally shorter than the hot-rolled seamless pipe. Than the wall thickness in cold drawing seamless hot-rolled seamless pipe evenly. cold drawn seamless (CDS) tubes have closer dimensional tolerances, better surface finish and higher mechanical properties than the corresponding grades of hot finished seamless tubes. Cold Drawn Seamless Mechanical Steel tube and pipe is produced by drawing tube through a die or cold rolling it to give it a more uniform diameter. For this reason Cold Drawn Seamless Mechanical Steel tube is stronger than other types of steel tube. Cold Drawn Seamless Steel tube and pipe can be used as a finished product or can be machined. It is supplied with complete quality assurance and in full compliance with the British Standard BS EN 10305-1 grade E235 + C. Our standard Cold Drawn Seamless tube and pipe is supplied in approximately 3 metre and 6 metre lengths, but should you need a different size please call us on the number above before placing your order.

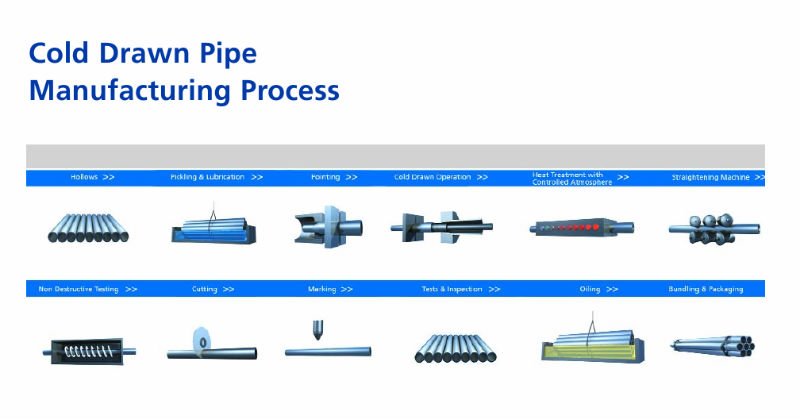

Cold drawn steel pipe manufacturing process :

Heat Treatment of Cold Drawn Seamless Steel Pipe Cold drawn seamless tube is used for high dimensional accuracy mechanical structure, hydraulic equipment and good surface finish cold drawn or cold rolled precision seamless steel tubes. High-precision drawing denotes the outer diameter size precision (tolerance) strict and external surface finish, roundness, straightness good thickness uniformity. Heat treatment of cold drawn seamless steel pipe: (1)cold drawn steel annealing: refers to the metal material is heated to the appropriate temperature, to maintain a certain time, and then slowly cooled heat treatment process. Common annealing process are: recrystallization annealing, stress relieving, ball annealing, fully annealed and so on. The purpose of annealing: mainly to reduce the hardness of the metal material, to improve the plasticity, or cutting processing to Liqie pressure processing, reduce the residual stress and improve the uniformity of microstructure and composition, heat treatment, after possible or tissue preparation. Cold Drawn Seamless tubing (also known as CDS). Cold Drawn Seamless tubes offer tight tolerances compared to Hot Finished Seamless tube, and offers stronger physical properties compared to other mechanical tubing. Precision cold drawn seamless steel tube CDS is popular in the hydraulics, being used to make hollowed chrome plated telescopic cylinders and hydraulic rods. It is also popular for large bore, heavy walled, high pressure hydraulic cylinders. Cold Drawn Seamless tubes also find uses in heavy equipment manufacturing such as cranes and garbage trucks. Precision cold drawn seamless steel tube General process of cold drawing A considerable proportion of the seamless tubes and pipes manufactured through the cold roll piercing technology undergo subsequent cold forming. The principal reasons behind cold drawing are: Precision cold drawn seamless steel tube Achievement of closer wall thickness and diameter tolerance Improvement in surface finish To enhance serviceability No premature failure Suitable for critical forming Such as 180 deg Bends Enhancement of mechanical properties of the tube Expansion of product mix towards the lower end of the OD and wall thickness scales.

THERE ARE THREE BASIC PROCESSES EMPLOYED FOR THE COLD DRAWING OF TUBE: Hollow drawing Stationery drawing or floating plug drawing and Drawing over a mandrel (also known as drawing on-the-bar) Annealing After the goods are cold drawn to sizes, the tubes are put on annealing furnace for heat treatment and normalising. Straightening Post annealing, the goods are passed through a seven roller straightening machine to achieve proper straightening of the tubes. Eddy current Post straightening, each tube is passed through eddy current machine to detect for surface cracks and other defects . Only the tubes that pass eddy current are fit for delivery to customers. Finishing Each tube is either oiled with corrosion resistant oil or varnished for surface protection and corrosion resistant as per customers requirement, each tube end is covered by plastic end caps to avoid damage in transit, the marking and specs are put and the goods are ready for dispatch.