Elbows 45° – 90° – 180° LR/SR

The function of a elbow is to change direction or flow in a piping system. By default, there are 5 opportunities, the 45°, 90° and 180° elbows, all three in the “long radius” version, and in addition the 90° and 180° elbows both in the “short radius” version.

Long and Short Radius

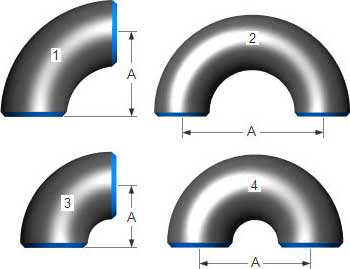

Elbows are split into two groups which define the distance over which they change direction; the center line of one end to the opposite face. This is known as the “center to face” distance and is equivalent to the radius through which the elbow is bent. The center to face distance for a “long” radius elbow, abbreviated LR always is “1.1/2 x Nominal Pipe Size (NPS) (1.1/2D)”, while the center to face distance for a short radius elbow, abbreviated SR even is to nominal pipe size. Here below, for example, you will find the center to face distance of four 2 inch elbows, (the “A” distance on the image).

| 1. 90°- 2″- LR : = 1.1/2 x (25,4 x 2) A = 76,2 mm2. 180°- 2″- LR : = 1.1/2 x (25,4 x 2) x 2 A = 152,4 mm3. 90°- 2″- SR : = 25,4 x 2 A = 50,8 mm4. 180°- 2″- SR : = (25,4 x 2) x 2 A = 101,6 mm |  |

45° Elbow

The function of a 45° elbow is the same as a 90° elbow, but the measurement of dimensions is different to that of the 90° elbow. The radius of a 45° elbow is the same as the radius of the 90° LR (1.1/2D). However, the center to face dimension is not equivalent to the radius as in 90° LR elbows. This is measured from each face to the point of intersection of the center lines perpendicular to each other, distances B on the image. This is due to the smaller degree of bend. Short radius 45° elbows are not available.

Butt Weld Elbow Applacation

The most applied version is the 90° long radius and the 45° elbow, while the 90° short radius elbow is applied if there is too little space. The function of a 180° elbow is to change direction of flow through 180°. Both, the LR and the SR types have a center to center dimension double the matching 90° elbows. These fittings will generally be used in furnesses or other heating or cooling units.

Butt Weld Elbow Types

In addition to the defined elbows, there is the Reducing Elbow, which is a elbow with various diameters on the ends. Because this elbow, for many suppliers it is not a standard item, and thus probably a high price with a long delivery time, the use of a “normal” elbow with a separate reducer is an option if the situation allows. Other degrees elbows can be machined from a standard elbow. Longer radius type, the center to face dimension e.g. is three times the nominal size (3D), even is available. Dimensions, dimensional tolerances etc. for long and short radius elbows are defined in ASME B16.9.

Wall Thickness of Elbows

The weakest point on an elbow is the inside radius. ASME B16.9 only standardizes the center to face dimensions and some “squareness” dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of an elbow.

The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting. Many providers of buttweld elbows (and tees) provide one schedule greater thickness so that sufficient wall thickness, after forming, remains.

An elbow is a pipe fitting which is used as a connection point between two lengths of pipes to produce a change in the direction of flow in the pipe, usually at an angle of 90°, 45° or 180°. Elbows are also commonly referred as bends, and are available in a range of materials such as stainless steel, carbon steel, alloy steel, nickel alloys, duplex, and cupro nickel. Also known as 90° bends, 90° elbows are manufactured as SR (Short Radius) elbows and LR (Long Radius) elbows. 45° elbows are typically made as LR (Long Radius) elbows. The long radius elbows have a center to end distance that is 1.5 times the NPS in inches (R=1.5D), while the short radius is equal to the NPS in inches (R=1.0D). Short radius elbows are generally used in tight areas, and long radius elbows are used when space is available and flow is more critical. We can also manufacture and supply carbon steel elbows and stainless steel elbows in non-standard size angles such as 60°, 100°, 120° or 150°.

ELBOWS: Mandrel method (Hot Forming)

One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called “mandrel” which allows the pipe to expand and bend simultaneously. Applicable to a wide size range. Elbows of steel pipe joints are used in the industrial plants and are mainly manufactured by the hot mandrel bending from raw material of straight steel pipe. Elbows are generally manufactured at elevated temperature by means of pushing, expanding and bending of pipes simultaneously, using the inner tool of mandrel. Characteristics of mandrel bending strongly depend on the integrated shape and dimensions of the mandrel. Elbows manufactured by using hot mandrel bending have advantages of small thickness deviation and shorter bending radius than those of any other bending method type.

[topswf swf=’https://www.haihaopiping.com/wp-content/uploads/2015/10/Seamless-Elbow-Made-by-Heat-Bending.swf’ width=’655′ height=’400′ quality=’best’ wmode=’transparent’ scale=’default’ flashvars=” allowfullscreen=’false’]