The ASME B16.5 standard governs the specifications for pipe flanges and flanged fittings used in various piping applications. This standard is widely recognized in industries such as oil and gas, petrochemicals, power generation, and water treatment, ensuring safe and reliable connections in piping systems.

ASME B16.5 Standard Pipe Flanges Dimensions:

ASME B16.5 Weld Neck Flange Dimensions (150lb-2500lb)

ASME B16.5 Slip On Flange Dimensions (150lb-1500lb)

ASME B16.5 Blind Flange Dimensions (150lb-2500lb)

ASME B16.5 Socket Weld Flange Dimensions (150lb-1500lb)

ASME B16.5 Lap Joint Flange Dimensions (150lb-2500lb)

ASME B16.5 Threaded Flange Dimensions (150lb-2500lb)

Haihao Group forged flanges engineering department,design,produce,inspect and supply our forged flanges according to the ASME B16.5 standard.The following is a detailed description of ASME B16.5 standard:

- 1. SCOPE

- 2. PRESSURE-TEMPERATURE RATINGS

- 3. COMPONENT SIZE

- 4. MARKING

- 5. MATERIALS

- 6. DIMENSIONS

- 7. TOLERANCES

- 8. PRESSURE TESTING

ASME B16.5 RF CL300 ASTM A105N weld neck flanges

2 PRESSURE-TEMPERATURE RATINGS

2.1 General

Pressure-temperature ratings are maximum allowable working gage pressures in bar units at the temperatures in degrees Celsius shown in Tables 2-1.1 through 2-3.19 for

the applicable material and class designation.Tables 2-1.1C through 2-3.19C list pressure-temperature ratings using psi units for pressure at the temperature in degrees Fahrenheit.For intermediate temperatures,linear interpolation is permitted.Interpolation between class designations is not permitted.

2.2 Flanged Joints

A flanged joint is composed of separate and independent, although interrelated components: the flanges, the gasket, and the bolting, which are assembled by another influence, the assembler. Proper controls must be exercised in the selection and application for all these elements to attain a joint that has acceptable leak tightness. Special techniques, such as controlled bolt tightening,are described in ASME PCC-1.

2.3 Ratings of Flanged Joints

2.3.1 Basis. Pressure-temperature ratings apply to flanged joints that conform to the limitations on bolting in para. 5.3 and on gaskets in para. 5.4, which are made up in accordance with good practice for alignment and assembly (see para. 2.2). Use of these ratings for flanged joints not conforming to these limitations is the responsibility of the user.

2.3.2 Mixed Flanged Joints. If the two flanges in a flanged joint do not have the same pressure–temperature rating, the rating of the joint at any temperature is the lower of the two flange ratings at that temperature.

2.4 Rating Temperature

The temperature shown for a corresponding pressure rating is the temperature of the pressure-containing shell of the component. In general, this temperature is the same as that of the contained fluid. Use of a pressure rating corresponding to a temperature other than that of the contained fluid is the responsibility of the user, subject to the requirements of applicable codes and regulations. For any temperature below −29°C (−20°F), the rating shall be no greater than the rating shown for −29°C (−20°F). (See also paras. 2.5.3 and 5.1.2.)

2.5 Temperature Considerations

2.5.1 General.

Use of flanged joints at either high or low temperatures shall take into consideration the risk of joint leakage due to forces and moments developed in the connected piping or equipment. Provisions in paras. 2.5.2 and 2.5.3 are included as advisory with the aim of lessening these risks.

2.5.2 High Temperature.

Application at temperatures in the creep range will result in decreasing bolt loads as relaxation of flanges, bolts, and gaskets takes place. Flanged joints subjected to thermal gradients may likewise be subject to decreasing bolt loads. Decreased bolt loads diminish the capacity of the flanged joint to sustain loads effectively without leakage. At temperatures above 200°C (400°F) for Class 150 and above 400°C (750°F) for other class designations, flanged joints may develop leakage problems unless care is taken to avoid imposing severe external loads, severe thermal gradients, or both.

2.5.3 Low Temperature.

Some of the materials listed in Tables 1.1-1 and 1.1-2, notably some carbon steels, may undergo a decrease in ductility when used at low temperatures to such an extent as to be unable to safely resist shock loading, sudden changes of stress, or high stress concentration. Some codes or regulations may require impact testing for applications even where temperatures are higher than −29°C (−20°F). When such requirements apply, it is the responsibility of the user to ensure these requirements are communicated to the manufacturer prior to the time of purchase.

2.6 System Hydrostatic Testing

Flanged joints and flanged fittings may be subjected to system hydrostatic tests at a pressure of 1.5 times the 38°C (100°F) rating rounded off to the next higher 1 bar (25 psi) increment. Testing at any higher pressure is the responsibility of the user, taking into account the requirements of the applicable code or regulation.

2.7 Welding Neck Flanges

Ratings forwelding neck flanges covered by ASME B16.5 standard are based upon their hubs at the welding end having thickness at least equal to that calculated for pipe having 276 MPa (40,000 psi) specified minimum yield strength.In order to ensure adequate flange hub thickness for flange sizes NPS 2 and larger, the bore of a welding neck flange, dimension B in the various dimensional tables,shall not exceed Bmax determined as follows:

Bmax=Ah(1- CoPc/50,000)

where

Ah=tabulated hub diameter,beginning of chamfer as listed in the dimensional tables

Bmax=maximum permissible diameter for the bore of a welding neck flange

Co=14.5 when pe is expressed in bar units or 1.0 when pe is expressed in psi units

Pc=ceiling pressure value at38°C(100°F), Nonmandatory Appendix A,Tables A-1 and A-2

The resultant units for diameter Bmax are the same as those entered for diameter A. The tabulated ratings for welding neck flanges are independent of components to which they may be attached, and the pressure rating of the flange shall not be exceeded. Attachment welds should be made in accordance with the applicable code or regulation.See para.6.7 and Figures 1 through 3 for weld end dimensional requirements.

2.8 Straight Hub Welding Flanges

2.8.1 Hub Dimensions.Straight hub welding flanges have hubs of uniform thickness (see Figure 4).Except as described in paras.2.8.2 through 2.8.4,the straight hub welding flanges shall have dimensions and tolerances of the welding neck flanges of the same size and class set forth in Tables 8,11,14,16,18,20,and 22 (Tables 8C,11C, 14C,16C,18C,20C,and 22C).In Figure 4 the tolerances described in section 7 are applicable.

2.8.2 Length Through Hub.The length through hub shall be 229 mm (9 in.)for NPS 4 and smaller and 305mm (12 in.)for larger than NPS 4.Other lengths may be furnished by agreement between the end user and manufacturer.

2.8.3 Bore.The bore diameter B shall be equal to the B dimension of the welding neck flange.Other bores may be furnished by agreement between the end user and manufacturer. In no case shall the bore diameter exceed the bore of the same size and class lapped flange.

2.8.4 Hub End.The standard flange shall be provided with square cutend.The end user may specify welding end preparation in accordance with para.6.7.

2.9 Multiple Material Grades

Material for flanges and flanged fittings may meet the requirements of more than one specification or the requirements of more than one grade of a specification listed in Table 1.1-1. In either case, the pressure-temperature ratings for any of these specifications or grades may be used provided the material is marked in accordance with para. 4.2.8.

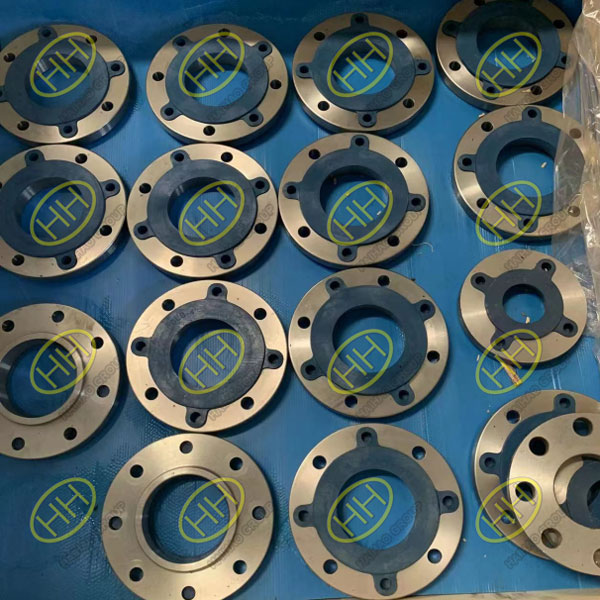

At Haihao Group, we specialize in providing a full range of ASME B16.5 pipe flanges and flanged fittings. Whether you’re looking for weld neck flanges, slip-on flanges, blind flanges, or any other type, we have the expertise and products to meet your specific needs.

If you want to learn more about our product offerings or have any inquiries, please feel free to contact us. We look forward to partnering with you for all your piping needs.