At Haihao Group, we are excited to share with you the incredible application of the submerged arc welding (SAW) process in pipeline construction. As a leading provider of innovative solutions for the oil, gas, and petrochemical industries, we have witnessed firsthand the transformative power of SAW in ensuring the integrity and longevity of pipelines.

Unparalleled Efficiency and Productivity: The SAW process excels in delivering high welding speeds, making it highly efficient for large-scale pipeline projects. With its automatic and continuous wire feed, SAW significantly reduces welding time, boosting productivity and reducing overall project timelines. This allows for faster completion of pipeline installations, leading to cost savings and increased operational efficiency.The SAW process has emerged as a game-changer, revolutionizing pipeline welding with its exceptional efficiency, reliability, and superior quality. Let’s delve into the remarkable benefits and applications of SAW in pipeline construction.

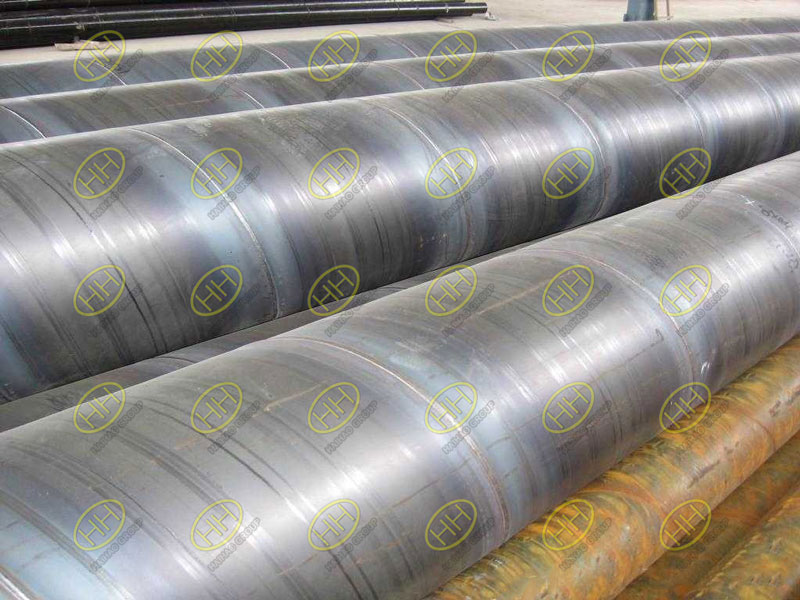

Spiral submerged arc welding steel pipes SSAW pipes

Impeccable Quality and Strength: Pipeline integrity is of utmost importance, and the SAW process ensures uncompromising quality and strength in welded joints. The controlled environment created by the flux blanket protects the weld from contaminants, resulting in sound and defect-free welds. The inherent characteristics of SAW, such as deep penetration and excellent fusion, guarantee robust and reliable connections that withstand high-pressure and corrosive environments.

Versatility for Various Pipeline Materials: The SAW process accommodates a wide range of pipeline materials, including carbon steel, stainless steel, and alloy steel. Whether it’s for transporting crude oil, natural gas, or hazardous chemicals, SAW provides the versatility to handle diverse pipeline requirements. The adaptability of SAW to different materials ensures the utmost compatibility and performance in demanding pipeline applications.

The operation of submerged arc welding

Enhanced Safety and Environmental Considerations: Safety and environmental protection are at the forefront of pipeline construction. The SAW process minimizes the risk of human error and operator exposure to hazardous fumes, as it is largely automated and operates under a protective flux blanket. Furthermore, the controlled welding conditions reduce the release of harmful emissions, ensuring compliance with stringent environmental regulations.

Unleashing Innovation and Expertise: At Haihao Group, we combine the power of the SAW process with our extensive industry experience and technical expertise. Our skilled professionals employ advanced SAW techniques and state-of-the-art equipment to deliver flawless welds, surpassing industry standards and client expectations. We prioritize innovation and continuously invest in research and development to stay at the forefront of pipeline welding technology.

Choose Haihao Group for Unmatched Pipeline Solutions: When it comes to pipeline construction, trust Haihao Group as your reliable partner. Our utilization of the SAW process, along with our commitment to quality and customer satisfaction, sets us apart in the industry. We are dedicated to providing tailored solutions, precise craftsmanship, and unwavering support throughout your pipeline project.

Experience the Power of SAW with Haihao Group: Unlock the full potential of your pipeline projects with the unparalleled capabilities of submerged arc welding. Contact Haihao Group today and discover how our expertise and cutting-edge SAW technology can elevate the efficiency, strength, and reliability of your pipelines. Together, let’s build a future where pipelines are the epitome of excellence.