There are many varieties of steel tubes, and the steel grades (types) used are not the same. The chemical composition of the steel tubes of the same variety may also be different, but the steel tubes can meet the relevant technical requirements after heat treatment.

The heat treatment process of steel tube

The heat treatment process of steel tube mainly includes the following 5 categories:

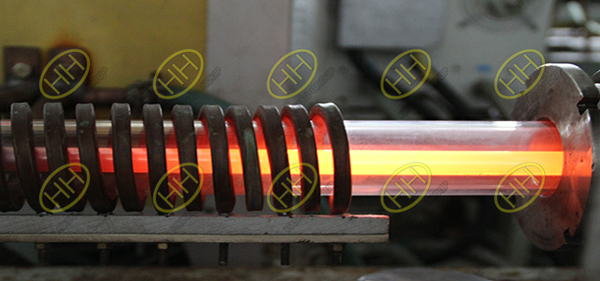

1.Quenching + high-temperature tempering (also known as tempering treatment)

The steel tube is heated to the quenching temperature, so that the internal structure of the steel tube is transformed into austenite, and then cooled rapidly at a rate greater than the critical quenching speed, so that the internal structure of the steel tube is transformed into martensite, and then combined with high-temperature tempering, finally the steel tube structure is transformed into uniform tempered sostenitic structure.

Quenching and high temperature tempering of steel tubes

This process can not only improve the strength and hardness of steel tube, but also combine the strength, plasticity and toughness of steel tube.

2.Normalizing (also known as normalizing)

After the steel tube is heated to the normalizing temperature and the internal structure of the steel tube is completely transformed into austenitic structure, the heat treatment process is cooled with air as the medium. Normalizing results in different metallic structures, such as pearlite , bainite, martensite, or a mixture of them…

Normalizing of steel tube

This process can not only refine grain, uniform composition and eliminate stress, but also improve the hardness and cutting performance of steel tube.

3.Normalizing + tempering

After the steel tube is heated to the normalizing temperature and the internal structure of the steel tube is completely transformed into austenitic structure, it is cooled in the air and then combined with the tempering process .The structure of steel tube is tempered ferrite + pearlite , or ferritic + bainite, or tempered bainite , or tempered martensite, or tempered sostenite .

Normalizing + tempering of steel tubes

This process can stabilize the internal structure of steel tube and improve the plasticity and toughness of steel tube.

4.Annealing

A heat treatment process in which the steel tube is heated to the annealing temperature and kept warm for a certain period of time, then slowly cooled to a certain temperature with the furnace and then removed from the oven for cooling.

Annealing of steel tube

Functions of the process:

Reduce the hardness of the steel tube, improve its plasticity, to facilitate the subsequent cutting or cold deformation processing;

(2) fine grain, eliminate tissue defects, uniform internal organization and composition, improve the performance of steel pipe or prepare for the subsequent process;

(3) eliminate the internal stress of the steel pipe, in order to prevent deformation or cracking.

5.Solid solution treatment

The steel tube is heated to the solution temperature, so that carbides and various alloying elements are fully and evenly dissolved in the austenite, and then rapidly cooled, so that the carbon and alloying elements cannot be separated out, and the heat treatment process of single austenite is obtained.

Solid solution treatment of steel tubes

Functions of the process:

The internal organization of the uniform steel tube, the composition of the uniform steel tube;

(2) eliminate the hardening in the processing process, in order to facilitate the subsequent cold deformation processing;

Restore the corrosion resistance of stainless steel.

As a professional pipe supplier,we supply steel pipes in different specification,standards,materials.If you want to know more about our products,please feel free to contact us.Email:sales@haihaogroup.com